The woodworking industry in Canada in 2025 shows signs of growth and adaptation to various market dynamicss:

Market Growth and Size: The Canadian woodworking industry is expected to reach a market size of $18.9 billion in 2025, with the industry projected to grow over the next five years. This growth is supported by a focus on sustainability, eco-friendly practices, and the integration of technology in manufacturing processes.

- Sustainability and Circular Economy: There’s a notable trend towards sustainability, with an emphasis on using reclaimed wood and eco-friendly practices. This trend is partly driven by consumer demand for environmentally responsible products.

- Technological Innovations: The adoption of automation, CNC machines, and other advanced woodworking machinery is increasing, aiming for higher precision and efficiency in production.

- Customization and Personalization: There’s a growing demand for custom-made and personalized wooden products, which is boosting the market for smaller, artisanal shops as well as larger manufacturers.

Data from the Past Two Years:

- Softwood Lumber Market: Over the past couple of years, there has been a stabilization in the softwood lumber market with seasonal price fluctuations returning to more predictable patterns post the volatility caused by the global health crisis. The industry has shown resilience, with sawmills adjusting production in response to demand to maintain price stability.

- Employment and Industry Challenges: Employment in woodworking, particularly in sawmills and wood preservation, has seen a decrease over the past 15 years, but the industry has faced challenges like labor shortages, which have driven up wages. The industry has also been navigating through economic factors such as the U.S.-Canada softwood lumber dispute and the impact of natural events like wildfires on log supply.

Regional and Market Expansion:

Canada has been expanding its export markets beyond the U.S., with significant exports to Asia, particularly China and Japan, although the U.S. remains the primary market.

Challenges:

The industry faces challenges from fluctuating lumber prices, international trade disputes, and the need for continuous adaptation to new technologies and consumer preferences. There’s also a noted consolidation trend in the industry, which might affect smaller players.

While the woodworking industry in Canada is experiencing growth, it is also navigating through a complex landscape of economic, environmental, and technological changes.

Ref:https://customcy.com/blog/wood-industry-statistics/; https://www.statista.com/outlook/io/manufacturing/material-products/wood/canada

How is the market of tungsten carbide blades in Canadian wood processing industry?

The market for tungsten carbide blades within the Canadian wood processing industry is robust and growing, driven by several key factors:

Current Market Trends:

- Durability and Efficiency: Tungsten carbide blades are favored for their exceptional hardness, longevity, and resistance to wear, which are critical in the high-volume, high-abrasion environment of wood processing. These qualities result in longer tool life and reduced downtime for blade replacements, thereby enhancing operational efficiency.

- Technological Adoption: The Canadian wood processing sector has seen an increase in the adoption of advanced machinery, including CNC equipment, which often requires high-performance blades like those made from tungsten carbide. This technology enables precision cutting and reduces waste, further promoting the use of carbide blades.

- Market Expansion: The demand for tungsten carbide is not limited to traditional wood processing but extends to areas like furniture manufacturing, laminates, and particle boards, where precision and durability are paramount. This versatility broadens the market for carbide blades.

- Industry Growth: The Canadian wood industry, including sawmills and wood product manufacturing, contributes significantly to the economy. With trends towards increased wood product exports and domestic consumption, the demand for efficient cutting tools like tungsten carbide blades is on the rise.

Challenges and Considerations:

- Cost: Tungsten carbide blades are more expensive than alternatives like steel. However, the cost per part or cut can be lower due to their superior longevity, which is a critical consideration for manufacturers looking to optimize their cost structures.

- Supply and Price Fluctuations: The global supply of tungsten, predominantly controlled by China, can lead to price volatility, affecting the cost of carbide blades. This might influence purchasing patterns or push for recycling initiatives to manage costs.

- Environmental and Health Concerns: While tungsten carbide itself is not particularly hazardous, the dust from cutting operations can pose health risks if not managed properly. This necessitates investments in dust collection systems for worker safety, which can impact the overall economics of using carbide blades.

Market Outlook:

- The market for tungsten carbide in Canada, particularly for blades used in wood processing, is expected to grow as the industry continues to focus on efficiency, quality, and sustainability. The ongoing demand for wood products both domestically and internationally supports this growth. Additionally, innovations in blade technology and manufacturing processes are likely to further enhance the market position of tungsten carbide blades.

- Companies like Epic Tool in Canada are at the forefront of supplying high-quality carbide tools, indicating a strong local market presence and expertise in this sector.

The market for tungsten carbide blades in the Canadian wood processing industry is characterized by growth driven by the need for durable, high-performance cutting tools, although it faces challenges related to cost, supply chain dynamics, and health considerations.

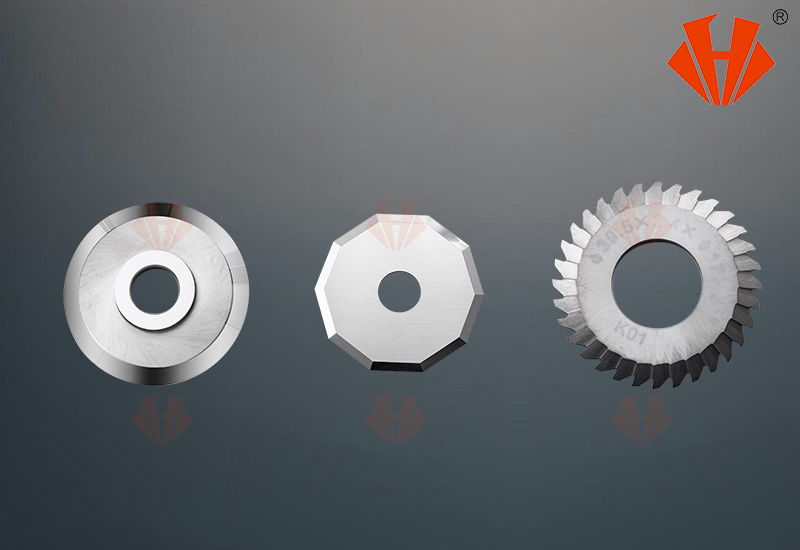

HUAXIN CEMENTED CARBIDE(https://www.huaxincarbide.com) manufactures a wide variety of blades for wood industry,Tungsten carbide woodworking reversible knives,indexable knives are suitable for different cutting heads and spiral planning cutter, such as: groove cutter, multi-function cutter, planing cutter and spindle moulder and so on, for cutting, grooving and rebating with a long life time.

Contact: lisa@hx-carbide.com

Post time: Feb-13-2025