In industries relying on precision cutting, the longevity of industrial blades directly impacts efficiency and cost-effectiveness. Proper industrial blade maintenance not only reduces downtime but also maximizes the tungsten carbide tool life, known for its exceptional durability. In this blog, we share five practical tips to keep your tungsten carbide blades in top condition, ensuring consistent performance across various applications.

1. Regular Cleaning for Optimal Performance

Dirt, debris, and material residues can accumulate on industrial blades during cutting operations, leading to increased friction and wear. Regular cleaning is essential for industrial blade maintenance:

- ▼Use a soft brush or compressed air to remove particles after each shift.

- ▼For stubborn residues, use a mild solvent compatible with tungsten carbide to avoid damaging the blade surface.

- ▼Avoid abrasive cleaning tools that could scratch the blade, reducing its cutting efficiency.

By keeping blades clean, you prevent premature wear and extend tungsten carbide tool life, especially for high-precision tasks.

2. Proper Storage to Prevent Damage

Improper storage can expose blades to moisture, dust, or accidental impacts, compromising their integrity. To maximize tungsten carbide tool life:

- ▼Store blades in a dry, temperature-controlled environment to prevent corrosion.

- ▼Use protective cases or blade sleeves to avoid edge chipping or surface scratches.

- ▼Keep blades separate from other tools to prevent accidental contact and damage.

Proper storage ensures that your tungsten carbide blades remain sharp and ready for use, minimizing replacement costs.

3. Use the Right Blade for the Material

Tungsten carbide blades are renowned for their durability, but using them on incompatible materials can shorten their lifespan. For effective industrial blade maintenance:

- ▼Match the blade to the material being cut (e.g., metal, wood, composites) to avoid excessive stress.

- ▼Ensure the blade’s edge geometry and coating are suitable for the application.

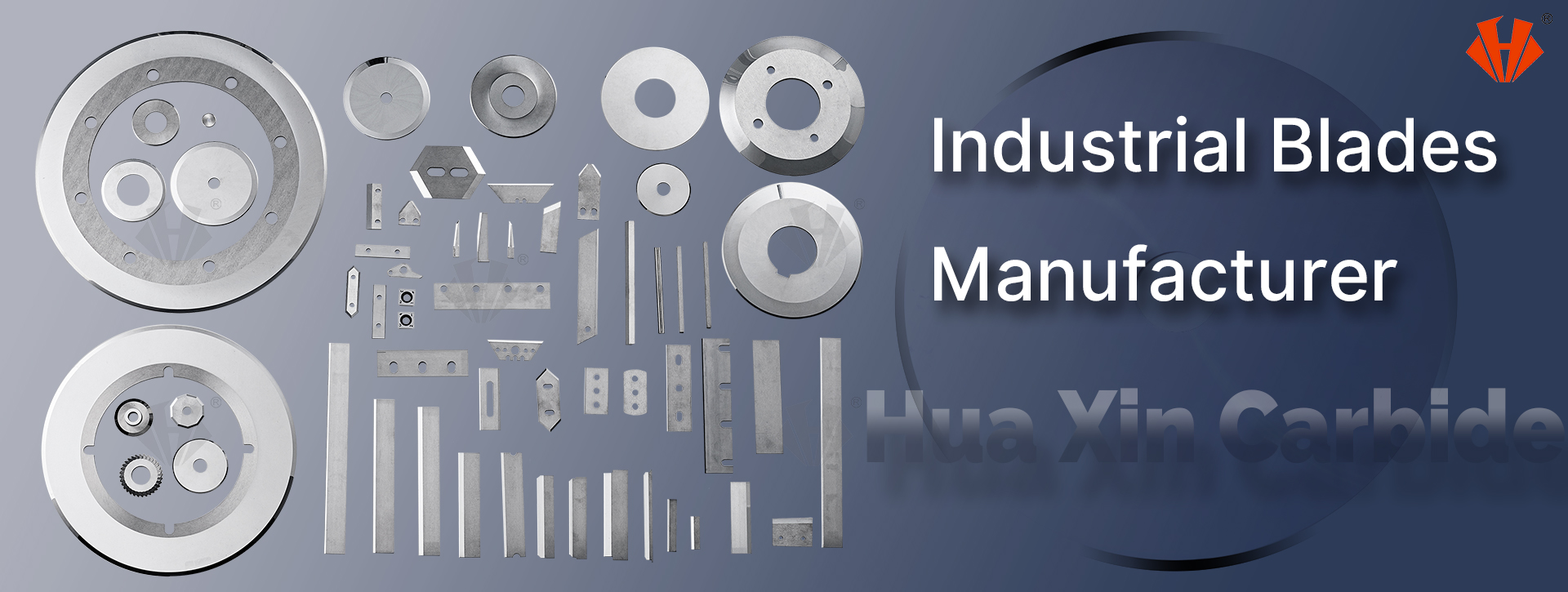

HUAXIN CEMENTED CARBIDE provides premium tungsten carbide knives and blades for our customers from different industries across the world. The blades can be configured to fit machines used in virtually any industrial application. Blade materials, edge length and profiles, treatments and coatings can be adapted for use with many industrial materials, ensuring optimal performance and longevity.

4. Monitor Blade Wear and Sharpen When Needed

Even durable tungsten carbide blades will wear over time. Regular inspection is key to industrial blade maintenance:

- ▼Check for signs of wear, such as reduced cutting efficiency or visible edge dullness.

- ▼Sharpen blades using appropriate grinding tools designed for tungsten carbide, ensuring the original edge geometry is maintained.

- ▼Avoid over-sharpening, which can weaken the blade structure.

By addressing wear early, you can extend tungsten carbide tool life and maintain consistent cutting quality.

5. Implement Proper Operating Conditions

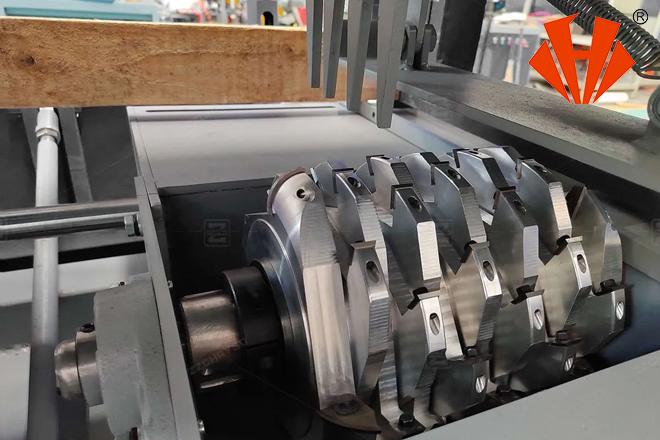

Excessive heat, speed, or pressure can accelerate blade wear, even for robust tungsten carbide blades. To protect your tools:

- ▼Operate machinery within recommended speed and feed rates to minimize heat buildup.

- ▼Use adequate coolant or lubrication during cutting to reduce friction and thermal stress.

- ▼Avoid overloading the blade, which can cause chipping or cracking.

These practices not only enhance industrial blade maintenance but also leverage the inherent durability of tungsten carbide, reducing downtime and replacement frequency.

Why Choose Tungsten Carbide Blades?

Tungsten carbide blades are a top choice for industrial applications due to their exceptional hardness and wear resistance. By following these maintenance tips, you can fully capitalize on their durability, ensuring cost-effective and reliable performance. Whether you’re cutting metal, wood, or composites, proper care is the key to extending tungsten carbide tool life.

Ready to optimize your cutting operations? Contact us for expert guidance on selecting the right blades for your needs:

- ▲Email: lisa@hx-carbide.com

- ▲Website: https://www.huaxincarbide.com

- ▲Tel & WhatsApp: +86-18109062158

Get free blade selection advice tailored to your industry and start maximizing your tool life today!

Investing in industrial blade maintenance is a small effort that yields significant returns in efficiency and cost savings. By cleaning, storing, and using your tungsten carbide blades correctly, you can extend their lifespan and maintain peak performance. With premium solutions from HUAXIN CEMENTED CARBIDE, you’re equipped to tackle any cutting challenge with confidence.

Start implementing these tips today and see the difference in your tungsten carbide tool life!

Post time: Feb-21-2025