Applications of Tungsten Carbide Slitting Blades in Corrugated Paper for Packaging

Introduction

In the packaging industry, corrugated paper plays a vital role due to its durability, recyclability, and cost-effectiveness. One crucial step in the production of corrugated packaging is slitting, which involves cutting the paper into the desired widths for various applications. Tungsten carbide slitting blades have emerged as the preferred choice for this process due to their ability to handle tough materials and maintain edge retention. This article delves into the applications of tungsten carbide slitting blades in corrugated paper for packaging, highlighting their benefits and the advantages of custom solutions.

Tungsten Carbide Slitting Blades: The Ideal Choice for Corrugated Paper

Handling Tough Materials

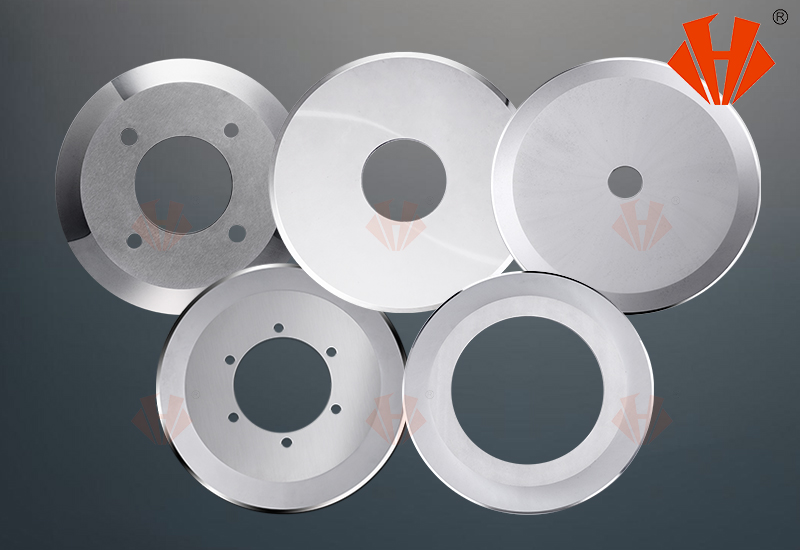

Corrugated paper, known for its strength and rigidity, poses unique challenges during the slitting process. Traditional blades often struggle with maintaining sharpness and edge retention when cutting through this tough material. Tungsten carbide slitting blades, however, excel in these conditions.

Tungsten carbide is a composite material composed of tungsten carbide particles embedded in a cobalt matrix. This combination results in a blade that is extremely hard and wear-resistant. According to industry experts, tungsten carbide blades can withstand the abrasive nature of corrugated paper, maintaining a sharp edge for extended periods. This ensures clean and precise cuts, minimizing waste and improving production efficiency.

Edge Retention and Longevity

Another significant advantage of tungsten carbide slitting blades is their edge retention and longevity. Unlike traditional blades, which dull quickly when cutting corrugated paper, tungsten carbide blades retain their sharpness for much longer. This reduces the frequency of blade changes, minimizing downtime and maximizing production uptime.

The longevity of tungsten carbide blades also translates to cost savings for manufacturers. With fewer blade replacements required, the overall cost of slitting operations is reduced, contributing to improved profitability.

Benefits of Custom Tungsten Carbide Slitting Blades

In the highly competitive packaging industry, manufacturers are constantly seeking ways to differentiate their products and improve efficiency. Custom tungsten carbide slitting blades offer a solution that meets these needs.

Tailored to Specific Applications

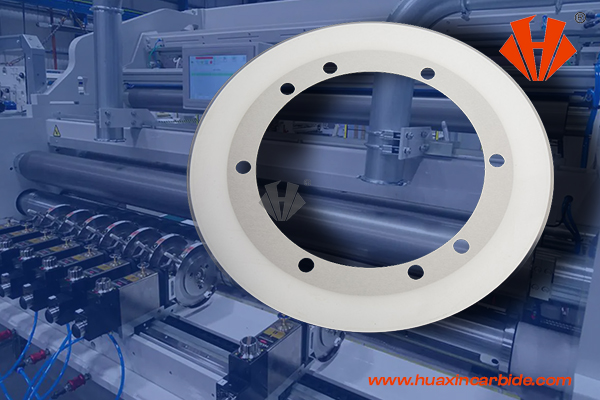

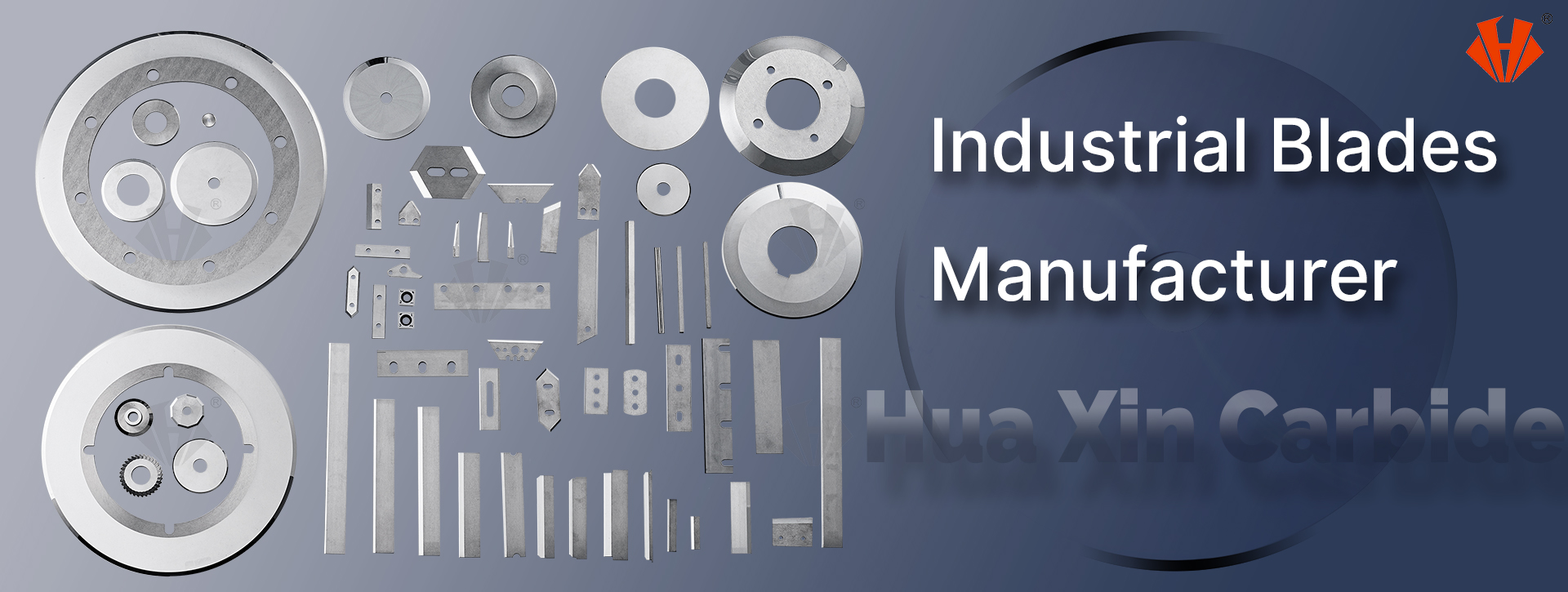

Huaxin, a leading industrial machine knife solution provider, specializes in manufacturing custom tungsten carbide slitting blades. Their products, including industrial slitting knives, machine cut-off blades, and related accessories, are used in more than 10 industries, including corrugated board, packaging, and more.

By working with Huaxin, manufacturers can obtain slitting blades tailored to their specific applications. Whether it’s a particular paper grade, slitting width, or production speed, Huaxin’s expertise in material science and manufacturing ensures that the blades meet the unique requirements of each application.

Enhanced Performance and Reliability

Custom tungsten carbide slitting blades offer enhanced performance and reliability compared to off-the-shelf options. The tailored design ensures optimal cutting efficiency, minimizing waste and improving product quality. Additionally, the blades are manufactured to strict quality control standards, ensuring consistent performance and longevity.

Contact Information

For more information about Huaxin’s tungsten carbide slitting blades and custom solutions for the packaging industry, please contact:

- Email: lisa@hx-carbide.com

- Website: https://www.huaxincarbide.com

- Tel & Whatsapp: +86-18109062158

Conclusion

Tungsten carbide slitting blades are the ideal choice for slitting corrugated paper in the packaging industry. Their ability to handle tough materials, maintain edge retention, and offer custom solutions makes them indispensable tools for manufacturers seeking to improve efficiency and profitability. With Huaxin as a reliable partner, manufacturers can obtain high-quality, custom tungsten carbide slitting blades tailored to their specific needs.

Post time: Mar-06-2025