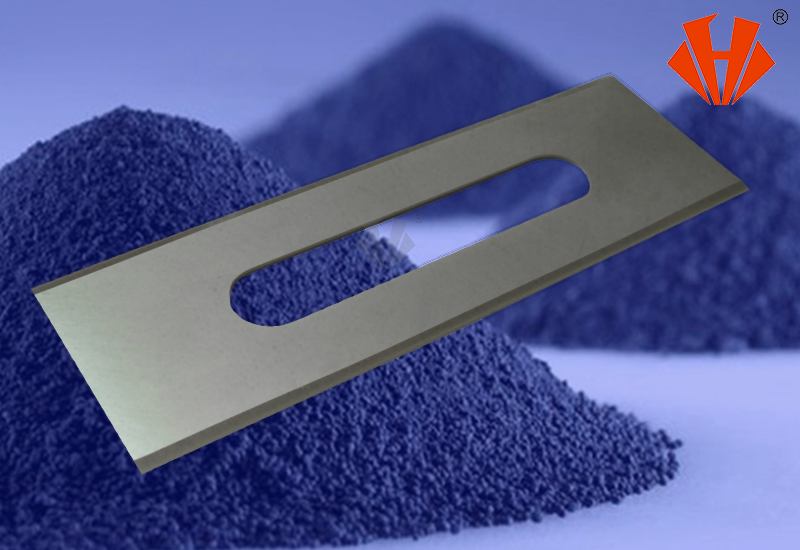

What Are Slotted Razor Blades?

Slotted razor blades are a specialized type of cutting blade commonly used in various industrial applications, including slitting, cutting, and trimming materials. They are typically made from high-quality materials like carbon steel, stainless steel, or tungsten carbide, depending on the intended use. The defining characteristic of slotted razor blades is the elongated slot or hole in the center of the blade, which differentiates them from conventional straight razor blades. This unique design offers a range of advantages, particularly in terms of precision, efficiency, and safety.

These blades are widely used in industries such as packaging, paper production, textiles, food processing, and more, where precise cuts are essential. The slotted design allows for easier handling and installation, particularly in automated or high-speed production environments.

Advantages of Slotted Razor Blades

Slotted razor blades offer several advantages over traditional straight blades, making them a popular choice in various industries:

- Precision Cutting: The sharpness and design of slotted razor blades ensure smooth and precise cuts, even on challenging materials such as plastics, films, and textiles. This level of precision helps manufacturers maintain high-quality standards and reduce waste.

- Durability and Longevity: High-quality slotted razor blades, particularly those made from tungsten carbide or other hard materials, offer exceptional durability. These blades retain their sharpness for longer periods, reducing the frequency of blade replacements and downtime in production.

- Ease of Handling and Installation: The central slot or hole allows for easy and quick installation of the blades into cutting machines, reducing setup time in production lines. This feature is particularly useful for industries with high-volume cutting needs, where machine efficiency is crucial.

- Cost-Effectiveness: While slotted razor blades may initially seem more expensive, their durability and efficiency can lead to long-term cost savings. Reduced blade replacements, minimal downtime, and improved cutting precision all contribute to a more cost-effective production process.

- Safety: Slotted razor blades offer enhanced safety features compared to other cutting blades. The design minimizes the risk of accidental injury during blade installation or operation, as the blades can be handled more securely.

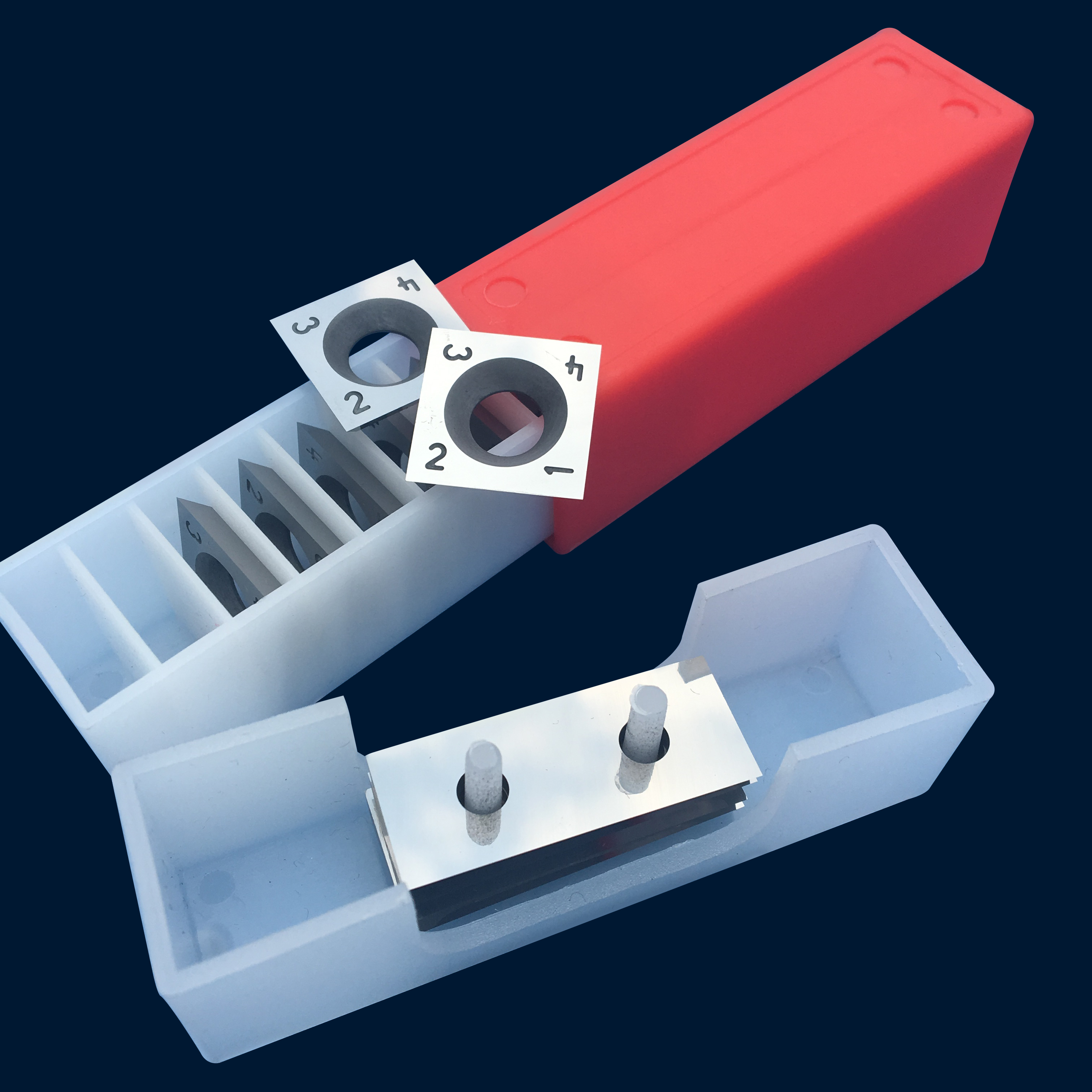

Safety Packaging of Slotted Razor Blades

Safety is a critical consideration when handling razor blades, and slotted razor blades are no exception. Due to their sharp edges, these blades can pose a significant risk of injury if not handled properly. Therefore, manufacturers ensure that slotted razor blades are packaged with safety in mind.

Blades are typically wrapped in protective materials such as plastic or cardboard to prevent accidental cuts. The packaging often includes safety warnings, instructions for handling, and guidelines for proper disposal. In addition, some packaging designs include blade dispensers or protective covers that allow users to safely remove the blades without coming into direct contact with the cutting edge.

Slotted Razor Blades for Industrial Slitting

One of the primary applications of slotted razor blades is in industrial slitting, a process where large rolls of material—such as paper, film, or foil—are cut into smaller widths. This process requires precision and sharpness to ensure clean and accurate cuts, and slotted razor blades are ideal for the job.

In industrial slitting, the blades are installed in slitting machines, where they rotate at high speeds to slice through the material. The slotted design of the blade provides better alignment and easier replacement, making it a practical choice for high-speed manufacturing environments. Additionally, the central hole allows the blade to be securely mounted in the machine, reducing the risk of vibration or misalignment that could affect the quality of the cut.

Why Choose Slotted Razor Blades from Huaxin Cemented Carbide?

When selecting slotted razor blades for industrial applications, it's important to consider the quality and reliability of the manufacturer. Huaxin Cemented Carbide is a leading manufacturer known for producing high-performance slotted razor blades that meet the stringent demands of industries worldwide.

1. Premium Materials: Huaxin uses premium cemented carbide, a material known for its hardness and resistance to wear and corrosion. This ensures that their slotted razor blades maintain sharpness and performance over extended periods, reducing the need for frequent replacements.

2. Precision Engineering: The company is known for its precise manufacturing processes, ensuring that each blade is accurately shaped and finished to meet the exact specifications required for various industrial applications. This level of precision ensures that the blades provide clean, consistent cuts.

3. Customizable Solutions: Huaxin offers a range of blade sizes and configurations to meet the specific needs of different industries. Whether you need blades for paper slitting, film cutting, or other applications, Huaxin provides tailored solutions to suit your requirements.

4. Reliable Performance: With a reputation for producing durable, high-performance blades, Huaxin Cemented Carbide is trusted by industries that rely on precision cutting. Their blades help businesses maintain operational efficiency and reduce downtime, ensuring a consistent and reliable production process.

Why Do Slotted Razor Blades Have Holes in Them?

The hole or slot in a slotted razor blade serves several practical purposes:

- Ease of Installation: The central hole allows the blade to be securely mounted on a spindle or shaft in cutting machines. This feature simplifies the installation process, especially in high-speed production lines where quick blade changes are often necessary.

- Enhanced Safety: The hole can also serve a safety function by reducing the exposed surface area of the blade. This reduces the chances of accidental cuts when handling or changing the blade.

- Weight and Balance: The hole can help reduce the weight of the blade without compromising its strength. A lighter blade can operate more efficiently at high speeds, reducing strain on the cutting machine and extending the life of the blade.

- Cost Efficiency: The design of the blade with a hole can reduce material costs, as less material is required to manufacture the blade while maintaining its strength and sharpness.

Which Slotted Blade Is Right for Your Industry?

Choosing the right slotted razor blade for your industry depends on several factors, including the materials being cut, the type of machinery used, and the level of precision required. For example:

- For Paper and Packaging: Slotted razor blades used in paper and packaging industries need to be highly durable and capable of making clean cuts through thick paper, cardboard, and other materials.

- For Film and Foil Cutting: In industries like food packaging, slotted razor blades must be sharp and capable of cutting through thin films without causing deformation or damage to the material.

- For Textile and Fabric Cutting: Slotted blades used in the textile industry must be able to cut through fabrics and textiles with precision, maintaining a smooth cutting edge to avoid fraying or tearing.

When selecting a slotted razor blade, it's important to consider the blade material, sharpness, and size to ensure optimal performance for your specific needs.

Slotted razor blades are an essential tool in many industrial applications, offering advantages such as precision cutting, durability, and safety. By choosing high-quality slotted razor blades, such as those from Huaxin Cemented Carbide, businesses can improve their production efficiency, reduce costs, and maintain high standards of quality in their products.

Post time: Nov-26-2024