Chemical Fiber Cutting Blades or Staple fiber cutter blade

Carbide blades have become indispensable in the woodworking industry due to their exceptional cutting performance, longevity, and versatility. These blades, particularly carbide turnover knives and reversible knives, are engineered for various applications, including rebating, tenoning, and general joinery. Chengduhuaxin Carbide, a leading manufacturer of high-quality carbide tools, offers a range of carbide insert knives that meet the diverse needs of the woodworking industry.

Understanding Carbide Blades in Woodworking

Carbide blades, especially those made of tungsten carbide, are renowned for their durability and resistance to wear and tear. Unlike traditional steel blades, carbide blades maintain their sharpness for extended periods, even under continuous use in demanding environments. This makes them ideal for woodworking tasks that require precision and consistency. Chengduhuaxin Carbide specializes in producing high-performance carbide blades, including carbide turnover knives and reversible knives, which are highly valued in woodworking for their cutting efficiency and extended lifespan.

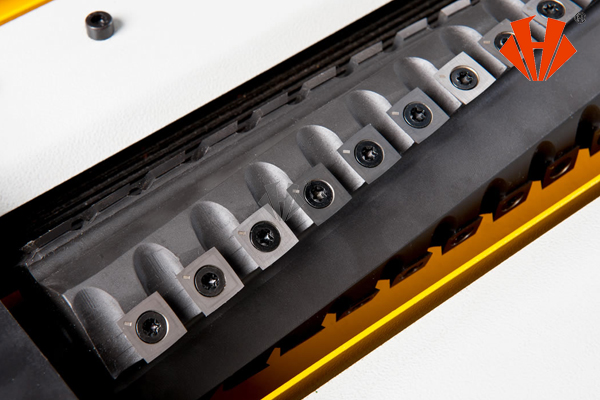

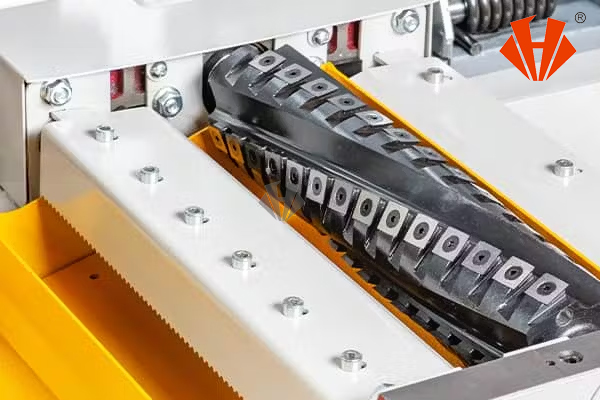

Carbide Turnover Knives and Reversible Knives

Carbide turnover knives, also known as reversible knives, are designed to be flipped or rotated when one edge becomes dull, thereby doubling or even quadrupling the lifespan of the blade. Chengduhuaxin Carbide offers these knives with either two or four cutting edges, allowing users to maximize their cutting time and reduce the frequency of blade replacements.

These knives are constructed using tungsten carbide, a material known for its extreme hardness and resistance to abrasion. This quality makes them ideal for high-precision woodworking applications, where maintaining a sharp edge is crucial for producing clean, accurate cuts.

Applications in Woodworking Machines

Carbide blades, including carbide turnover and reversible knives, are commonly used in rebating and tenoning operations. These processes are fundamental in creating joints for woodworking projects, such as cabinetry, furniture, and other wooden structures. The durability and precision of tungsten carbide reversible blades make them particularly suitable for use on machines like Wadkin, SCM, and Laguna, which are known for their reliability and accuracy in general joinery applications.

Carbide insert knives and reversible planer blades are also employed in other woodworking tasks, such as planing, moulding, and trimming. Their robust construction and sharp cutting edges ensure a smooth finish, reducing the need for additional sanding or finishing work. This efficiency is vital in high-volume production environments, where time and material savings are crucial.

Key Benefits of Using Carbide Blades in Woodworking

- Longevity and Durability: Carbide blades, particularly those made from tungsten carbide, offer significantly longer service life compared to traditional steel blades. They maintain their sharpness for an extended period, reducing the need for frequent replacements and minimizing downtime in woodworking operations.

- Precision Cutting: Carbide turnover knives and reversible knives from Chengduhuaxin Carbide are engineered to deliver precise cuts, ensuring high-quality results for every woodworking project. Their sharp edges provide clean, smooth cuts, which is essential for tasks like rebating, tenoning, and other joinery applications.

- Versatility: Carbide blades are versatile tools used across various woodworking machines and applications. Chengduhuaxin Carbide's range of solid carbide insert knives, reversible planer blades, and special reversible knives can be utilized on different machines, including Wadkin, SCM, and Laguna, enhancing their utility in diverse woodworking environments.

- Cost-Effectiveness: Although carbide blades may have a higher initial cost than traditional steel blades, their extended lifespan and reduced maintenance requirements make them a cost-effective choice in the long run. The ability to use multiple cutting edges before replacement further enhances their economic value.

Special Reversible Knives and Custom Solutions

- Chengduhuaxin Carbide also offers special reversible knives tailored to meet specific requirements in the woodworking industry. These custom-designed blades can be manufactured in various shapes and sizes to suit unique applications, ensuring optimal performance and compatibility with specialized woodworking machines. Whether you need a woodworking square solid carbide blade for intricate cuts or a cemented carbide insert for heavy-duty applications, Chengduhuaxin Carbide provides the solution.

Why Choose Chengduhuaxin Carbide?

- Chengduhuaxin Carbide has established itself as a trusted name in the production of high-quality carbide blades for the woodworking industry. Their commitment to using advanced manufacturing processes and premium-grade materials, such as tungsten carbide and cemented carbide inserts, ensures that their products meet the highest standards of performance and durability.The company's solid carbide insert knives and tungsten carbide inserts are designed to withstand the rigors of continuous use in demanding woodworking environments. With a range of products tailored to different applications, Chengduhuaxin Carbide provides versatile solutions that cater to the needs of professionals and craftsmen alike.

Carbide blades, including carbide turnover and reversible knives, are essential tools in the woodworking industry, providing superior cutting performance, durability, and cost-efficiency. Chengduhuaxin Carbide’s range of carbide insert knives, solid carbide blades, and special reversible knives offers a comprehensive solution for various woodworking applications, ensuring precision, longevity, and versatility. By choosing Chengduhuaxin Carbide, woodworking professionals can enhance their productivity, reduce downtime, and achieve the high-quality results needed in today's competitive market.

Post time: Sep-17-2024