When considering these blades for corrugated paper cutting, it's important to balance the initial investment with the long-term benefits in terms of performance, maintenance, and operational efficiency.

However, specific applications might require testing to confirm the advantages in your particular setup.

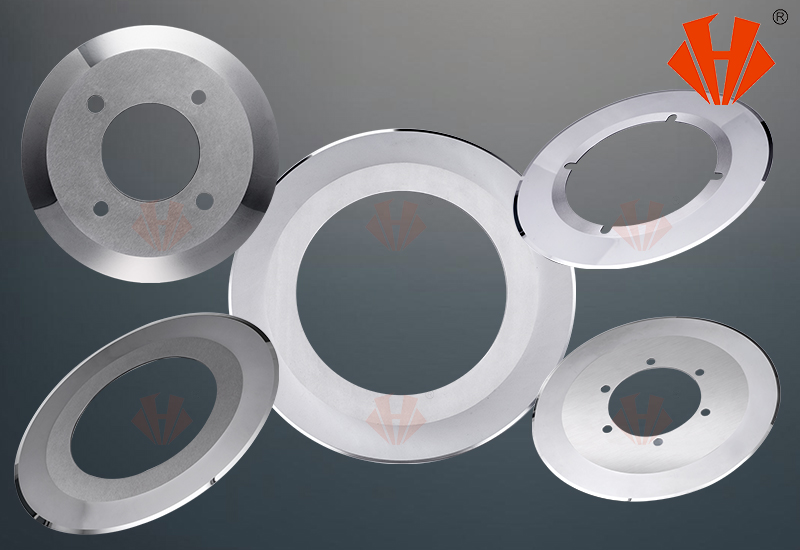

Circular tungsten carbide blades offer several advantages when used for cutting corrugated paper:

Durability and Longevity:

Hardness: Tungsten carbide is one of the hardest materials available, significantly outlasting blades made from steel or other materials. This hardness translates into longer life spans even under harsh cutting conditions.

Wear Resistance: The blades maintain sharpness over many cuts, reducing the frequency of blade changes and thus downtime in production.

Precision and Quality of Cut:

Clean Cuts: The exceptional hardness ensures cleaner cuts through corrugated materials, which can be thick and tough. This results in a higher quality finish, with less tearing or fraying of the paper.

Consistency: Tungsten carbide blades maintain their edge, ensuring consistent cut quality over time, which is crucial for maintaining product standards in manufacturing.

Efficiency:

Reduced Friction: These blades often have a lower coefficient of friction which can lead to less heat generation during cutting, potentially reducing the energy required for the cutting process.

Speed: The ability to maintain sharpness means that cutting speeds can be higher without compromising the quality of the cut, enhancing productivity.

Cost-Effectiveness:

Lower Maintenance Costs: Although tungsten carbide blades are initially more expensive, their longevity means fewer replacements, which can be cost-effective over time.

Reduced Downtime: With less need for blade changes or sharpening, operational efficiency increases, reducing labor and operational costs.

Versatility:

Adaptability: Tungsten carbide blades can be designed with various tooth configurations, suitable for different types of corrugated materials, thicknesses, and cutting speeds.

Safety:

Less Breakage: The robustness of tungsten carbide reduces the likelihood of blade breakage, which can be a safety hazard in high-speed cutting environments.

Environmental Impact:

Sustainability: Longer-lasting blades mean less waste from blade disposal. Also, fewer blade changes can contribute to a reduction in environmental impact from manufacturing new blades.

HUAXIN CEMENTED CARBIDE(https://www.huaxincarbide.com) manufactures a wide variety of blades for use in the paper slitting industry. Huaxin is your Industrial Machine Knife Solution Provider, our products include industrial slitting knives, machine cut-off blades, crushing blades, cutting inserts, carbide wear-resistant parts, and related accessories.

Contact: lisa@hx-carbide.com or call tel/whatsapp:+86-18109062158

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking,carbide circular knives for tobacco&cigarette filter rods slitting,round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging ,tape,thin film cutting,fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America,India,Turkey,Pakistan,Australia,Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers.

Contact us today and you will enjoy benefits of good quality and services from our products!

Post time: Aug-11-2025