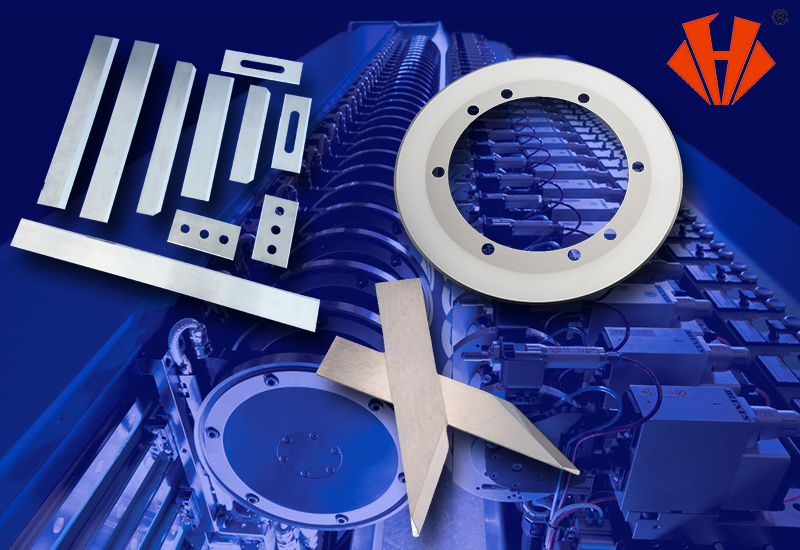

Types of Tungsten Carbide Blades in Industrial Applications

Tungsten carbide blades are a vital component in various industries, known for their durability, hardness, and resistance to wear and tear. These high-performance blades are widely used in cutting, grinding, and machining applications, where precision and longevity are crucial. As industries continue to demand better performance and efficiency, tungsten carbide blades have emerged as the material of choice due to their exceptional properties. In this article, we will explore the different types of tungsten carbide blades commonly used in industrial applications.

1. Standard Tungsten Carbide Blades

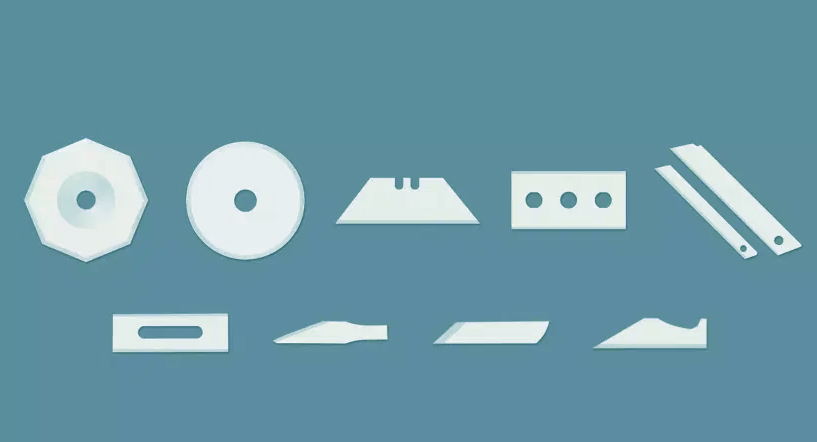

The most common type of tungsten carbide blades are the standard blades, which are often used in general cutting applications. These blades are known for their hardness and ability to cut through a wide range of materials, including metals, plastics, and composites. Standard tungsten carbide blades are often found in saws, cutters, and rotary tools. Their high resistance to wear and corrosion makes them ideal for industries like manufacturing, construction, and mining.

2. Insert Tungsten Carbide Blades

Insert blades are a type of tungsten carbide blade designed to be inserted into tool holders or machines. These blades are often used in turning, milling, and machining processes, particularly in the metalworking industry. Insert blades are highly versatile, as they can be replaced without the need to replace the entire tool, providing a cost-effective solution for operations requiring frequent blade changes. Insert tungsten carbide blades are available in a variety of shapes, including square, round, and triangular, depending on the specific cutting application.

3. Cemented Carbide Blades

Cemented carbide blades are composed of tungsten carbide particles bonded together with a metallic binder, typically cobalt. These blades are designed for high-performance cutting tasks and offer superior edge retention and wear resistance. Cemented carbide blades are often used in industries where high precision and extended tool life are required, such as the aerospace, automotive, and manufacturing sectors. These blades are particularly effective in cutting hard materials like steel, aluminum, and even titanium.

4. Carbide-Coated Blades

Carbide-coated blades are typically made from steel or other base materials and coated with a thin layer of tungsten carbide. The coating enhances the blade’s wear resistance, hardness, and overall performance, making them ideal for heavy-duty applications. These blades are commonly used in industries like food processing, woodworking, and paper manufacturing, where high-quality cuts and durability are essential. Carbide-coated blades are also popular in cutting tools for the automotive and aerospace industries due to their ability to withstand high temperatures and pressures.

Tungsten carbide blades play a crucial role in industrial applications that require durability, precision, and longevity. From standard blades to insert and cemented carbide varieties, these blades offer tailored solutions for various sectors, including manufacturing, automotive, aerospace, and more. As industries continue to evolve and demand more efficient tools, tungsten carbide blades will remain a cornerstone of high-performance cutting technologies.

Huaxin Cemented Carbide(https://www.huaxincarbide.com) company,a national high-tech enterprise specializing in the research, development, manufacturing, and sales of cemented carbide industrial knives and blades more than 20 years,is your Industrial Machine Knife Solution Provider.

Post time: Dec-05-2024