To protect the cutting knives of a cigarette paper-making machine, it's important to implement a series of maintenance practices and operational guidelines to ensure their longevity and optimal performance. Here are some effective strategies:

1. Regular Maintenance and Inspection

- Frequent Inspections: Regularly inspect the knives for any signs of wear, chipping, or dullness. Early detection of damage can prevent further deterioration and reduce the risk of blade failure.

- Scheduled Sharpening: Implement a schedule for sharpening the knives based on usage and wear patterns. Sharp blades are less likely to cause tearing or ragged cuts, which can lead to machine jams and damage.

2. Use of High-Quality Materials

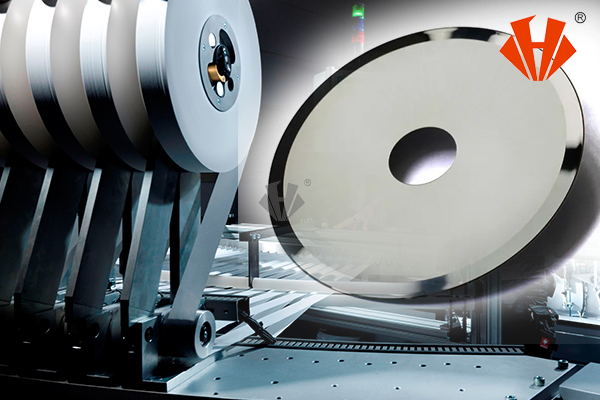

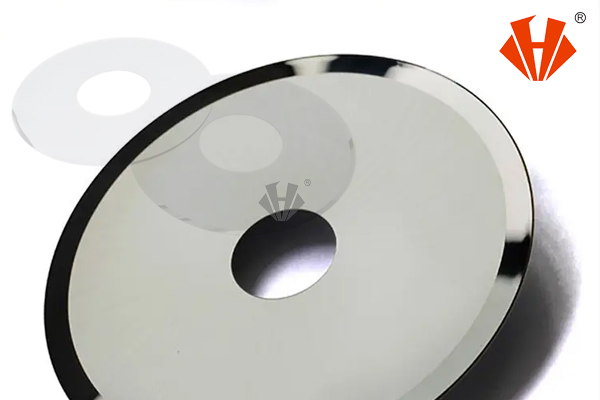

- Choose High-Quality Blades: Invest in blades made from superior materials like tungsten carbide or high-speed steel. These materials offer excellent wear resistance, edge retention, and durability.

- Coated Blades: Consider using blades with anti-corrosion coatings or other protective layers that resist wear and reduce friction.

3. Proper Machine Operation

- Correct Alignment: Ensure that the knives are properly aligned in the machine. Misalignment can cause uneven wear and increase the likelihood of chipping or breakage.

- Optimal Tension and Pressure Settings: Adjust the machine’s tension and pressure settings to the recommended levels for the specific type of cigarette paper. Excessive force can damage the knives, while too little pressure can cause uneven cuts.

4. Maintain Clean Working Conditions

- Regular Cleaning: Keep the cutting area clean and free from paper dust, debris, and residue. Accumulated debris can cause the knives to dull more quickly and affect their performance.

- Use of Lubricants: Apply appropriate lubricants to the machine components to reduce friction and wear on the knives. Ensure that the lubricants used are compatible with the materials of the blades and do not cause corrosion.

5. Proper Handling and Storage

- Safe Handling: Handle the knives with care during installation, removal, or replacement to avoid dropping or bending them, which can cause chipping or damage.

- Safe Storage: Store spare knives in a clean, dry, and safe environment, preferably in protective covers or cases to avoid any physical damage or exposure to moisture.

6. Train Machine Operators

- Operator Training: Ensure that machine operators are well-trained in the correct use and maintenance of the cutting knives. Proper handling and operation can significantly reduce the chances of damage.

7. Monitor Machine Performance

- Monitor Vibration and Noise Levels: Unusual vibrations or noises can indicate issues such as knife misalignment, dullness, or mechanical problems. Address these promptly to prevent knife damage.

By implementing these protective measures, you can extend the lifespan of the cutting knives in your cigarette paper-making machine, ensuring efficient operation and reducing maintenance costs.

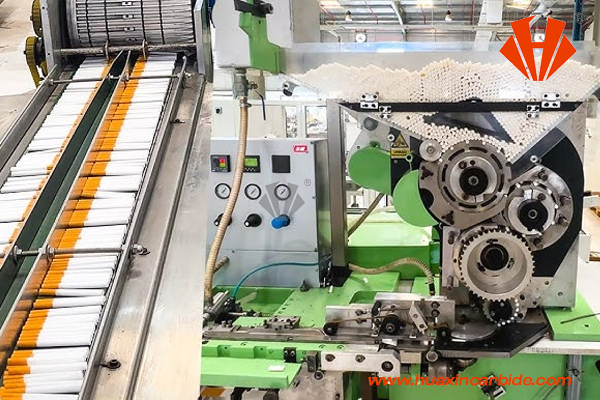

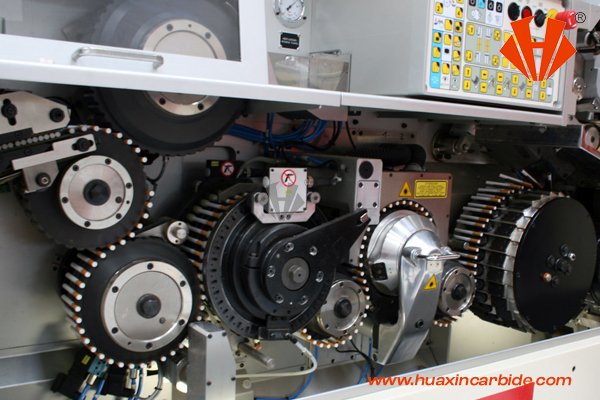

Cigarette rolling machine includes four main parts: silk feeding, forming, cutting and weight control, our products are mainly used in the cutting part. To reduce the time cost of repair and maintenance to a minimum,mirror surface treatment and coating services have been done to our blades.

In the processing of cutting tobacco, a sharp and precise cutting is needed. Because tobacco leaves can be quite tough and difficult to cut through. A dull knife can not only damage the tobacco but can also lead to uneven cuts, which can impact the quality of the tobacco. With a tungsten knife, however, the blade remains sharp even after multiple cuts, ensuring that the tobacco is cut precisely and with ease.

Another advantage of using a tungsten knife for cutting tobacco is that it is easy to maintain. Unlike other types of knives, tungsten knives require very little maintenance. They do not rust or corrode, and they can be cleaned easily with just soap and water. This means that the knife can be used for years without needing to be sharpened or replaced, making it a cost-effective choice for tobacco cutters.

HUAXIN CEMENTED CARBIDE provides premium tungsten carbide knives and blades for our customers from different industries across the world.The blades can be configured to fit machines used in virtually any industrial application. Blade materials, edge length and profiles, treatments and coatings can be adapted for use with many industrial materials

Post time: Oct-12-2024