Introduction

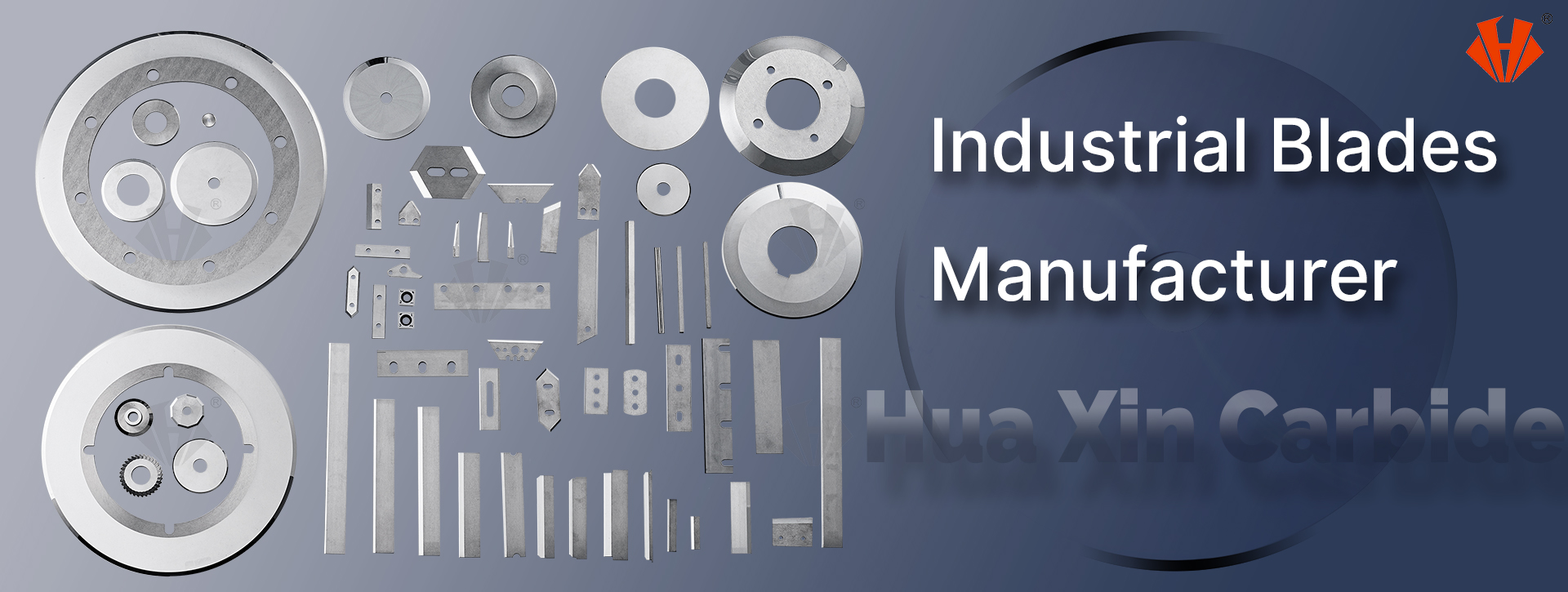

Industrial slitting is a crucial process in material processing, involving the cutting of various materials such as metals, plastics, and textiles into desired widths or shapes. The choice of cutting tool plays a vital role in the efficiency and quality of the slitting process. Tungsten carbide blades have emerged as a powerful option due to their exceptional properties, making them ideal for demanding industrial environments.

The Versatility of Tungsten Carbide in Industrial Slitting

Tungsten carbide blades are renowned for their hardness, wear resistance, and sharpness, making them versatile in a wide range of industrial slitting applications.

Metal Slitting

In metal slitting, tungsten carbide blades excel due to their ability to maintain a sharp edge even when cutting through hard and abrasive materials. This ensures precise and clean cuts, minimizing waste and improving production efficiency. According to industry experts, tungsten carbide blades are particularly effective in slitting thin gauge metals, such as stainless steel and aluminum, where precision and edge retention are paramount.

Plastic Slitting

Plastics, known for their variability in hardness and thickness, pose unique challenges in the slitting process. Tungsten carbide blades, with their high wear resistance, are well-suited to handle these materials. They maintain a sharp cutting edge, ensuring consistent and high-quality cuts across various plastic types. This versatility makes tungsten carbide blades a preferred choice for plastic slitting applications in industries such as packaging and automotive.

Textile Slitting

In the textile industry, tungsten carbide blades are used for slitting fabrics and other materials with precision. Their sharpness and durability ensure clean cuts, minimizing fabric damage and waste. This is particularly important in high-end textile applications, where the quality of the final product depends on the precision of the cutting process.

The Toughness of Tungsten Carbide Blades

The toughness of tungsten carbide blades is a key factor that makes them ideal for demanding industrial environments. Tungsten carbide is a composite material composed of tungsten carbide particles embedded in a cobalt matrix. This combination results in a blade that is extremely hard and wear-resistant, capable of maintaining a sharp edge for extended periods even under heavy use.

Huaxin Cemented Carbide (www.huaxincarbide.com), a leading manufacturer of tungsten carbide blades, focuses on using advanced materials and manufacturing processes to produce blades that excel in hardness, wear resistance, and sharpness. Their commitment to quality ensures that tungsten carbide blades meet the highest standards in industrial slitting applications.

Benefits of Tungsten Carbide Blades in Industrial Slitting

The use of tungsten carbide blades in industrial slitting offers several benefits:

- Improved Efficiency: Tungsten carbide blades maintain a sharp edge longer, reducing the frequency of blade changes and downtime. This leads to improved production efficiency and cost savings.

- High-Quality Cuts: The precision and sharpness of tungsten carbide blades ensure clean and consistent cuts, minimizing waste and enhancing the quality of the final product.

- Versatility: Tungsten carbide blades can be used in a wide range of industrial slitting applications, from metals to plastics and textiles, making them a versatile tool for various industries.

Contact Information

For more information about Huaxin Cemented Carbide’s tungsten carbide blades and other cutting tools for industrial slitting applications, please contact:

- Email: lisa@hx-carbide.com

- Website: https://www.huaxincarbide.com

- Tel & Whatsapp: +86-18109062158

Tungsten carbide blades are a powerful option for industrial slitting applications, offering exceptional hardness, wear resistance, and sharpness. Their versatility and toughness make them ideal for demanding environments, ensuring high-quality cuts and improved production efficiency. With Huaxin Cemented Carbide as a reliable partner, manufacturers can obtain high-quality tungsten carbide blades tailored to their specific needs.

Post time: Mar-12-2025