A Beginner's Guide to Tungsten Carbide Blades

Introduction

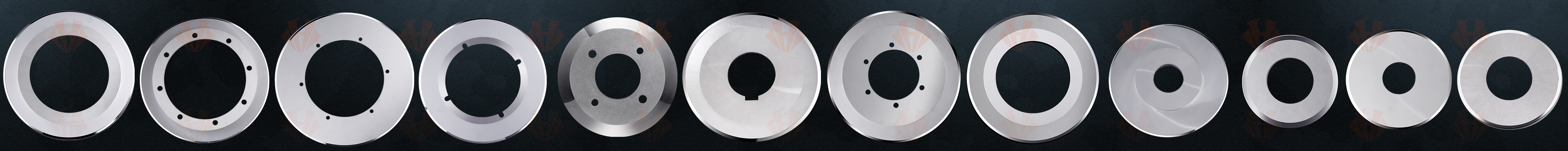

Tungsten carbide blades are renowned for their exceptional hardness, durability, and precision, making them indispensable in various industrial applications. This guide aims to introduce beginners to tungsten carbide blades, explaining what they are, their composition, and why they are highly valued in the manufacturing world.

What Are Tungsten Carbide Blades?

Tungsten carbide, also known as cemented carbide, is a composite material composed primarily of tungsten carbide particles bonded together with a binder, typically cobalt. This combination results in a material that is extremely hard and wear-resistant. Tungsten carbide blades leverage these properties to provide superior cutting performance and longevity.

Composition of Tungsten Carbide Blades

The composition of tungsten carbide blades primarily consists of tungsten carbide grains embedded in a cobalt matrix. The tungsten carbide grains provide the hardness and wear resistance, while the cobalt binder ensures the material maintains some degree of toughness and can be machined into the desired shapes. The exact composition can vary depending on the specific application, with some blades containing higher percentages of tungsten carbide for maximum hardness or more cobalt for improved toughness.

Why Tungsten Carbide Blades Are Prized for Their Hardness and Longevity

The hardness and longevity of tungsten carbide blades stem from their unique composition and manufacturing process. The high hardness of tungsten carbide grains makes the blades resistant to wear and tear, even when exposed to abrasive materials. Additionally, the cobalt binder helps distribute impact forces, preventing the blades from fracturing under stress. These properties combine to provide a cutting tool that maintains its sharpness over extended periods, reducing the need for frequent replacement.

Versatility Across Industries

Tungsten carbide blades are versatile and find applications in numerous industries, including woodworking, tobacco making, and more. In woodworking, they are used for cutting, routing, and shaping wood with precision and efficiency. In tobacco manufacturing, they are employed for slicing and processing tobacco leaves, ensuring consistent quality and output. Their ability to withstand high temperatures and maintain sharpness makes them ideal for these demanding applications.

Huaxin Cemented Carbide: Leading Manufacturer of Tungsten Carbide Blades

Huaxin Cemented Carbide is a renowned manufacturer of tungsten carbide blades, offering a comprehensive selection of grades and custom solutions tailored to meet the specific needs of diverse industries. Starting from powder through finished ground blanks, Huaxin's manufacturing process consistently delivers high-performance, reliable near-net shaped tools.

Huaxin specializes in manufacturing tungsten carbide blades, including custom, altered standard, and standard blanks and preforms. Their expertise in material science and manufacturing enables them to provide tailored solutions for every industry, addressing specialized customer application challenges.

Contact Information

For more information about Huaxin Cemented Carbide's tungsten carbide blades and custom engineering services, please contact:

- Email: lisa@hx-carbide.com

- Website: https://www.huaxincarbide.com

- Tel & Whatsapp: +86-18109062158

Tungsten carbide blades are an essential component in various industrial applications due to their hardness, durability, and precision. Huaxin Cemented Carbide stands out as a leading manufacturer, offering high-performance blades tailored to meet the specific needs of diverse industries. With their expertise and commitment to quality, Huaxin is the go-to choice for tungsten carbide blade solutions.

Post time: Feb-27-2025