Maintaining and Sharpening Tungsten Carbide Blades: Practical Advice for Maximizing Lifespan

Introduction

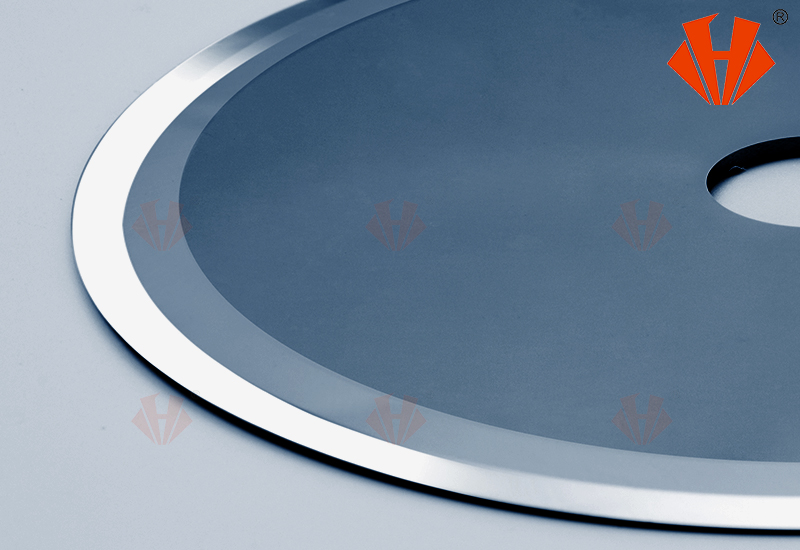

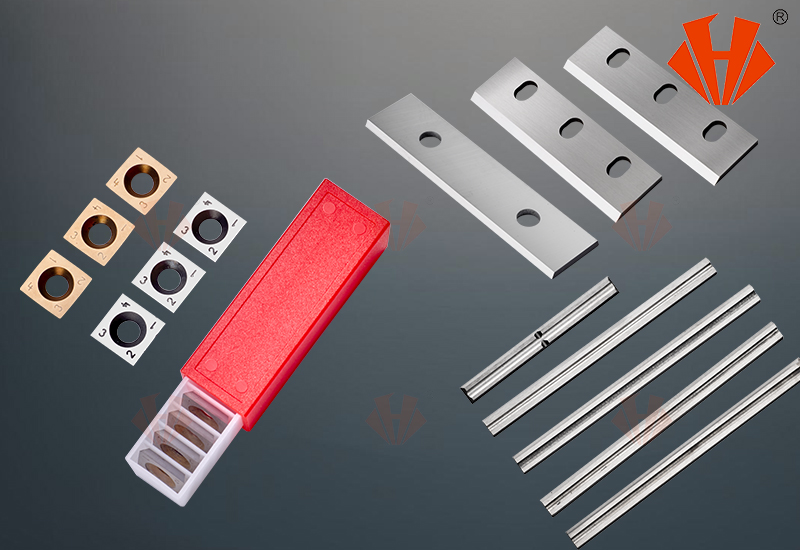

Tungsten carbide blades are renowned for their hardness, wear resistance, and cutting performance across various industries. However, to ensure they continue to deliver optimal results, proper maintenance and sharpening are essential. This article offers practical advice on cleaning, sharpening, and storing tungsten carbide blades to maximize their lifespan. We will also provide do’s and don’ts for users in different industries, ensuring that your blades remain in peak condition.

Cleaning Tungsten Carbide Blades

Do’s

- Regular Cleaning: Establish a routine for cleaning your tungsten carbide blades after each use. This removes debris, dust, and other contaminants that can dull the blade or cause premature wear.

- Use Mild Detergents: When cleaning, use mild detergents and warm water. Avoid harsh chemicals or abrasives that could damage the blade’s surface.

- Dry Thoroughly: After cleaning, ensure the blade is thoroughly dried to prevent rust and corrosion.

Don’ts

- Avoid Improper Cleaning Tools: Never use steel wool, brushes with metal bristles, or other abrasive materials to clean tungsten carbide blades. These can scratch the surface and reduce cutting performance.

- Neglect Regular Cleaning: Skipping regular cleaning can lead to a buildup of debris and contaminants, reducing the blade’s lifespan and cutting efficiency.

Sharpening Tungsten Carbide Blades

Do’s

- Use Specialized Sharpening Tools: Invest in specialized sharpening tools designed for tungsten carbide blades. These tools ensure precise and consistent sharpening, maintaining the blade’s edge integrity.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s guidelines for sharpening intervals and techniques. Over-sharpening can weaken the blade’s structure, while under-sharpening can reduce cutting performance.

- Regular Inspection: Regularly inspect the blade for signs of wear or damage. Address any issues promptly to prevent further deterioration.

Don’ts

- Avoid Improper Sharpening Techniques: Never attempt to sharpen tungsten carbide blades using improper techniques or tools. This can lead to uneven wear, chipping, or cracking of the blade.

- Neglect Sharpening: Ignoring the need for sharpening can dull the blade, reducing cutting efficiency and increasing the risk of damage during use.

Storing Tungsten Carbide Blades

Do’s

- Store in a Dry Environment: Keep tungsten carbide blades in a dry, rust-free environment to prevent corrosion.

- Use Blade Protectors: When not in use, store blades in protective sheaths or cases to prevent accidental damage.

- Label and Organize: Label and organize your blades to ensure easy identification and retrieval. This reduces the risk of using the wrong blade for a specific application.

Don’ts

- Avoid Exposure to Moisture: Never store tungsten carbide blades in damp or humid conditions. Moisture can cause rust and corrosion, reducing the blade’s lifespan.

- Improper Storage: Improper storage, such as leaving blades exposed or stacked loosely, can lead to damage or dulling.

Industry-Specific Do’s and Don’ts

Manufacturing

- Do: Regularly inspect blades for wear and sharpen as needed to maintain cutting precision.

- Don’t: Overuse dull blades, which can lead to increased material waste and reduced production efficiency.

Woodworking

- Do: Use specialized sharpening tools designed for tungsten carbide blades to maintain a sharp edge for precise cuts.

- Don’t: Attempt to sharpen blades using improper techniques, which can damage the blade’s structure.

Packaging

- Do: Clean blades regularly to remove debris and adhesive residue, ensuring clean cuts and preventing blade dulling.

- Don’t: Store blades in environments with high humidity, which can cause corrosion and reduce blade lifespan.

Contact Information

For more information on maintaining and sharpening tungsten carbide blades, or to inquire about our specialized sharpening tools and services, please contact:

- Email: lisa@hx-carbide.com

- Website: https://www.huaxincarbide.com

- Tel & Whatsapp: +86-18109062158

Proper maintenance and sharpening of tungsten carbide blades are crucial for maximizing their lifespan and cutting performance. By following the practical advice outlined in this article, you can ensure that your blades remain in peak condition, reducing downtime and operational costs. Remember to regularly clean, sharpen, and store your blades correctly, and always follow manufacturer guidelines and industry-specific best practices.

Post time: Mar-20-2025