In the world of industrial cutting, precision and durability are essential for achieving high-quality results. When it comes to cutting thin films in industries such as packaging, electronics, and textiles, using the right type of blade can make a significant difference in both efficiency and product quality. One such solution gaining increasing popularity is the 3-hole razor blade, a specialized tool designed to provide superior performance in film slitting and cutting applications.

What are 3-Hole Razor Blades?

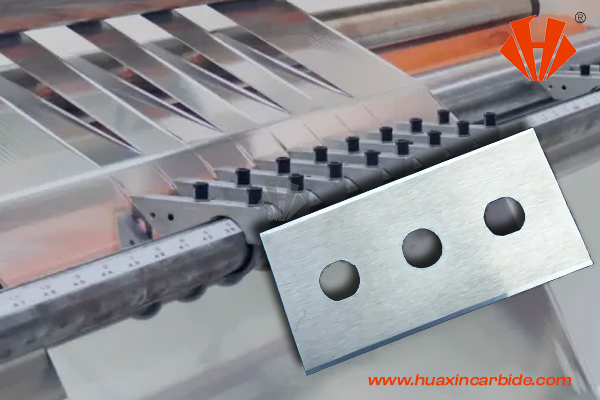

Also known as Industrial 3-hole razor blades, these cutting tools feature three precisely positioned holes along their surface. These holes play a critical role in improving the functionality and efficiency of the blade during the cutting process. While they are sometimes referred to as slotted hole blades or razor blades with three holes, the design and material composition of these blades allow them to tackle high-precision cutting tasks with ease.

Key Benefits of 3-Hole Razor Blades for Cutting Film

- Enhanced Precision in Cutting

One of the standout advantages of three holes razor blades is their ability to maintain consistent cutting quality. The three holes are strategically placed to reduce the risk of blade misalignment during operation. This leads to more accurate cuts and cleaner edges, which is particularly important when working with delicate materials such as thin film. Whether the application is for slitting plastic films, flexible packaging materials, or other thin substrates, the consistent sharpness and precision of a 3-hole razor blade ensure minimal material waste and a higher level of finished product quality.

- Improved Durability and Longevity

In industrial environments, blades must be able to withstand significant wear and tear, especially when cutting through tough materials like films or composite materials. Three holes razor slitter blades are designed with durability in mind. The three-hole configuration helps distribute cutting forces more evenly across the surface of the blade, resulting in reduced wear and longer-lasting performance. This not only increases the overall lifespan of the blade but also decreases the frequency of blade replacements, ultimately saving businesses time and money.

- Enhanced Stability During Operation

The three-hole design also improves the overall stability of the blade during operation. When mounted in a slitting machine or other industrial cutting equipment, these blades are held more securely, reducing the chances of blade wobble or movement that could affect cutting quality. This stability is crucial in high-speed cutting processes, where even the slightest misalignment can lead to defects in the film and reduced efficiency.

- Superior Material for High-Performance Cutting

Companies like Huxin Cemented Carbide (www.huaxincarbide.com) focus on the production of advanced thin film carbide blades. By using high-performance materials like cemented carbide, Huxin ensures that their razor blades not only offer superior sharpness but also exceptional hardness and wear resistance. Cemented carbide is well-known for its ability to withstand extreme conditions, making it the ideal material for blades used in industrial cutting applications where longevity and precision are critical.

- Reduced Friction and Heat Generation

Another significant advantage of razor blade with three holes is the reduction of friction between the blade and the material being cut. The three-hole design helps to disperse heat more effectively, preventing the blade from overheating and becoming less effective over time. This is particularly important when cutting films, as excessive heat buildup can deform the material, leading to imperfections in the final product. By maintaining a cooler cutting surface, these blades can achieve smoother cuts and extend the blade's lifespan.

- Versatility in Various Cutting Applications

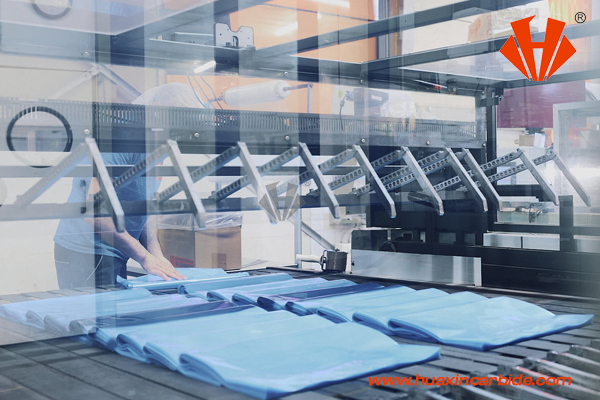

Three holes razor slitter blades are versatile and can be used across a wide range of industries that require precise cutting of thin films and other materials. They are ideal for use in film slitting machines, packaging production lines, and various other industrial applications where high-quality slitting is required. The uniformity in the design ensures that the blades perform consistently across different materials, whether it's plastic film, metal foils, or paper-based products.

- Reduced Blade Chatter and Vibration

The holes in the blade also play a role in reducing chatter and vibration during the cutting process. This is particularly beneficial when cutting at high speeds, where instability in the blade can lead to poor cuts and increased wear. The industrial 3-hole razor blades are engineered to minimize these issues, allowing for smoother operation and better results in the long run.

The three holes razor blades represent a technological advancement in the field of industrial cutting, particularly for thin film applications. Their design offers numerous advantages, from enhanced precision and durability to improved stability and performance. By choosing high-quality blades made from advanced materials like cemented carbide, companies can achieve superior results while reducing maintenance costs and downtime. Huxin Cemented Carbide exemplifies the potential of carbide technology, producing blades that excel in hardness, wear resistance, and sharpness, making them a trusted partner for industries in need of reliable, high-performance cutting tools.

For businesses involved in film cutting and slitting applications, investing in razor blades with three holes is a smart choice that can lead to better efficiency, lower operational costs, and, most importantly, higher-quality finished products.

Post time: Nov-18-2024