The System of Spiralling/Texturing Tools and Their Blades in Woodworking

In the realm of woodworking, the addition of texture and spirals to turned pieces adds not just visual appeal but also tactile interest, transforming simple forms into works of art. The System of Spiralling/Texturing tools is a specialized set of implements designed to enhance woodturning projects with intricate patterns, spirals, and textures. Here, we delve into this system, its components, and why tungsten carbide blades are the superior choice for these tools.

Understanding the Spiralling/Texturing System

Spiralling and Texturing Tools Overview:

Texturing Tool: This tool adds unique textures to the wood surface, creating effects like striations, whorls, or an orange peel finish. It typically features an interchangeable cutter that can work on both soft and hardwoods, although the result may vary based on wood grain and density.

Spiralling Tool: Used for creating spirals or flutes, these tools can produce both left and right-handed spirals. They often come with a system that includes a tool rest with indexed positions for consistent replication of spirals. Different pitch sizes can be achieved by changing the cutter or adjusting the tool’s angle.

Key Components:

- Handle: Usually made from wood for comfort and control, allowing for prolonged use without fatigue.

- Tool Rest: An integral part of the spiralling system, enabling precise control over the angle and depth of cut.

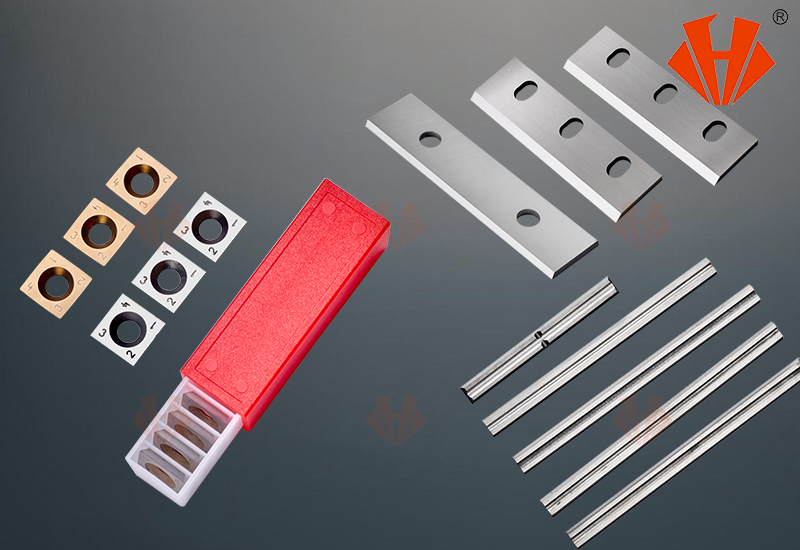

- Cutters: The heart of these tools, available in various configurations:

- Texturing Cutters: These come in one or more designs, often with a double-beveled edge or a specific profile to create different textures.

- Spiralling Cutters: Offered in sets, typically including different pitches (like 2mm, 4mm, 6mm) to achieve varied spiral effects.

The Advantage of Tungsten Carbide Blades

When it comes to the blades used in spiralling and texturing tools, tungsten carbide stands out as the material of choice for several compelling reasons:

Durability:

Tungsten carbide is renowned for its hardness (only surpassed by diamond), which means these blades maintain their edge significantly longer than traditional steel blades. This durability translates into extended tool life, reducing the frequency of replacements and sharpening.

Edge Retention:

The superior edge retention of tungsten carbide ensures that each cut remains precise over time, which is crucial for achieving consistent texturing and spiralling patterns. This quality is particularly beneficial in woodworking where precision can make a significant aesthetic difference.

Versatility:

These blades can cut through a variety of woods, from soft to hard, without losing their sharpness quickly. Their versatility makes them ideal for artisans who work with different wood types and projects.

Reduced Maintenance:

While tungsten carbide blades can be more challenging to sharpen due to their hardness, the need for sharpening is far less frequent. This aspect is especially appealing for those looking to minimize downtime and maintenance costs.

Efficiency:

The ability to cut cleanly through wood with minimal effort not only speeds up the process but also reduces the physical strain on the woodworker, allowing for more intricate designs with less effort.

Applications and Considerations

- Applications: These tools are used for embellishing turned items like goblets, spindles, candlesticks, and bowls, providing a decorative element that can be both subtle or pronounced based on the technique and tool used.

- Considerations: While tungsten carbide blades are an excellent investment, they do come with a higher initial cost. However, their longevity and performance often justify this expense. Also, users should be aware of the need for appropriate safety measures when working with these tools due to their sharpness and the resulting wood dust.

The System of Spiralling/Texturing tools, equipped with tungsten carbide blades, represents a pinnacle in woodworking tool technology, offering unparalleled control, precision, and durability. Whether you’re a professional woodturner or a hobbyist, investing in these tools can significantly elevate your woodturning projects, providing both artistic and functional benefits. Remember, the choice of material for your blades is as crucial as the technique; tungsten carbide not only stands up to the task but excels in it.

Reversible Planer Blades Knives are made of a premium carbide grade and are individually inspected to ensure quality and accuracy. Planer blades are used when working on wooden surfaces to help create perfectly planned surfaces. They can also be used to chamfer, and rebate edges. The size of the blade refers to the size of the planer that it will fit. It will outlast conventional HSS blades at least 20 times and produce a smoother, cleaner finish.

Huaxin Cemented Carbide manufactures tungsten carbide blades custom, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

custom-engineered blades

Leading manufacturer of industrial blades

www.huaxincarbide.com

contact: lisa@hx-carbide.com

Post time: Jan-11-2025