Three-hole razor blades, particularly those made from tungsten and carbide, are an indispensable tool in the Polyfilms industry. Their precision, durability, and ability to deliver clean cuts make them a go-to choice for film slitting applications. Manufacturers like Huxin Cemented Carbide continue to push the boundaries of blade technology, ensuring that the Polyfilms industry has access to cutting tools that enhance productivity and product quality.

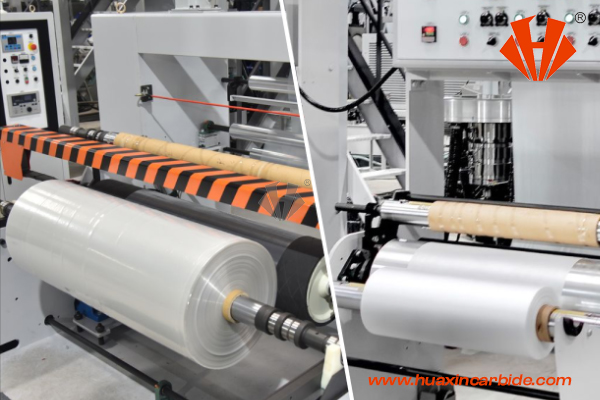

The Polyfilms industry relies heavily on precise and efficient cutting tools to produce high-quality products. One such tool that plays a vital role in the manufacturing process is the three-hole razor blade. These blades are specifically designed for use in film slitting machines, where they cut or slit thin materials like plastic films, tapes, and other substrates used in packaging and industrial applications. In this article, we will explore the benefits of three-hole razor blades in the Polyfilms industry and highlight key terms such as Film Slitter Blades, Tungsten Blades, Thin Film Slitting Knives, and Carbide Blades. We will also take Huxin Cemented Carbide Company as an example of a leading manufacturer of thin film carbide blades.

Importance of Film Slitter Blades in the Polyfilms Industry

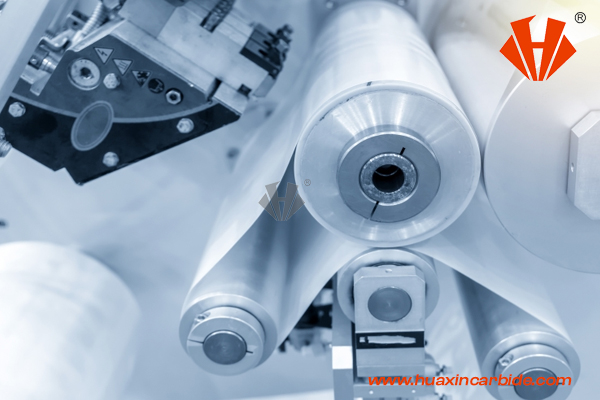

Film slitter blades are essential in the Polyfilms industry for achieving accurate and clean cuts. The slitting process involves cutting large rolls of film into narrower strips, which are then used for various applications, such as food packaging, adhesive tapes, and industrial films. The quality of the cut significantly impacts the final product’s performance, making the choice of blade critical.

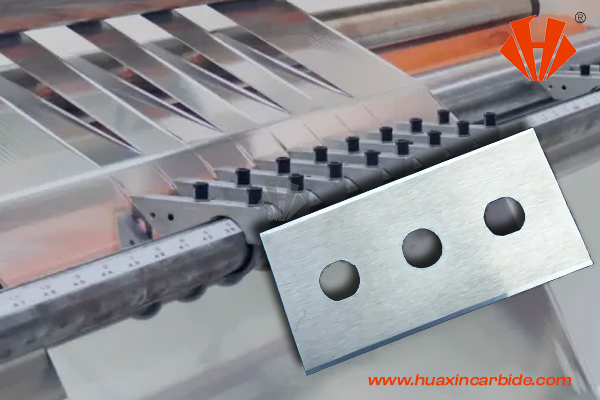

Three-hole razor blades are preferred in many applications due to their compatibility with most slitting machines. They offer the advantage of easy installation and provide excellent stability during cutting, ensuring minimal wobbling or misalignment, which can otherwise lead to defects or waste.

Tungsten and Carbide Blades: Durability and Precision

When it comes to blade material, Tungsten blades and carbide blades are two of the most popular options for slitting thin films. Tungsten is known for its incredible hardness and resistance to wear, making it ideal for slitting tasks that require longevity and precision. Carbide blades offer similar benefits but come with additional advantages in terms of their ability to maintain sharpness over extended periods.

Carbide, an alloy of tungsten, delivers excellent durability even when cutting through tough or abrasive materials. The wear-resistant properties of carbide blades reduce the frequency of blade replacements, improving overall efficiency and lowering operational costs.

Thin Film Slitting Knives: A Specialized Solution

For manufacturers who work with delicate and thin materials, such as plastic films, tapes, or thin laminates, specialized thin film slitting knives are essential. These blades are designed to provide clean cuts without damaging the material, ensuring that the slitting process is both efficient and precise. Carbide blades for tape and thin films are engineered to cut through these materials with minimal effort, providing high-quality results even at high cutting speeds.

Huxin Cemented Carbide: A Leader in Thin Film Blade Manufacturing

One of the leading manufacturers of thin film slitting knives is Huxin Cemented Carbide Company. Specializing in the production of carbide blades for the Polyfilms industry, Huxin provides a wide range of slitting solutions that meet the demanding requirements of the film industry. Their products are known for their exceptional quality, offering precise, clean cuts with minimal wear, ensuring that manufacturers can rely on consistent performance over long production runs.

Huxin Cemented Carbide focuses on using advanced materials and manufacturing processes to produce blades that excel in hardness, wear resistance, and sharpness. Their expertise in carbide technology makes them a trusted partner for businesses in need of high-quality thin film carbide blades.

Post time: Oct-15-2024