Introduction

Tungsten carbide blades are renowned for their exceptional hardness, wear resistance, and precision cutting capabilities. These properties make them ideal for a wide range of industrial applications, from woodworking to tobacco processing and corrugated paper slitting. In this article, we will provide an overview of the key industries benefiting from tungsten carbide blades, explaining how each benefits from their unique properties and including real-world use cases.

Woodworking Industry

The woodworking industry is one of the primary beneficiaries of tungsten carbide blades. These blades are used in a variety of woodworking tools, including circular saws, band saws, and router bits. Tungsten carbide’s hardness and wear resistance enable these blades to maintain a sharp edge for extended periods, reducing the need for frequent sharpening. This results in increased productivity and reduced operational costs.

Real-World Use Case

In furniture manufacturing, tungsten carbide blades are used to cut intricate patterns and shapes in wood. Their precision and durability ensure clean, accurate cuts, enhancing the overall quality of the finished product.

Tobacco Industry

The tobacco industry also relies heavily on tungsten carbide blades. These blades are used in cigarette making machines to slice tobacco leaves into thin strips. Tungsten carbide’s ability to maintain a sharp edge under continuous use ensures consistent and efficient tobacco slicing, which is crucial for producing high-quality cigarettes.

Real-World Use Case

In a large-scale tobacco processing plant, tungsten carbide blades are used in automated cutting machines that handle thousands of tobacco leaves per hour. Their wear resistance and precision ensure consistent cutting quality, reducing waste and improving production efficiency.

Corrugated Paper Industry

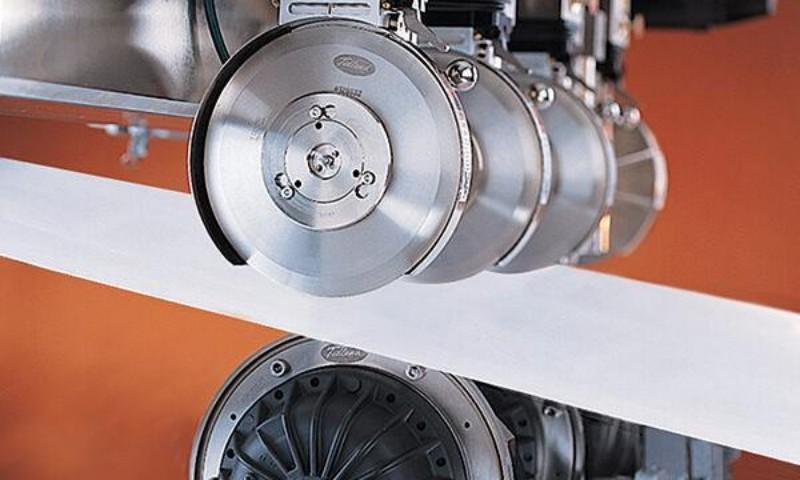

The corrugated paper industry benefits significantly from tungsten carbide blades used in slitting and cutting machines. These blades are designed to withstand the abrasive nature of corrugated paper, maintaining a sharp edge for extended periods. This ensures clean, accurate cuts, which is essential for producing high-quality packaging materials.

Real-World Use Case

In a corrugated paper mill, tungsten carbide blades are used in slitting machines to cut large rolls of corrugated paper into narrower strips. Their hardness and wear resistance enable the blades to handle the abrasive nature of corrugated paper, ensuring consistent cutting quality and reducing downtime for blade replacements.

Industrial Tools and Machinery

Tungsten carbide blades are also widely used in various industrial tools and machinery, including metal cutting tools, packaging machinery, and textile cutting equipment. Their exceptional hardness and wear resistance make them ideal for applications requiring high precision and heavy-duty cutting.

Real-World Use Case

In the automotive industry, tungsten carbide blades are used in metal cutting tools to process sheet metal for car body parts. Their precision and durability ensure accurate cuts, reducing waste and improving production efficiency.

Conclusion

Tungsten carbide blades offer numerous benefits across a wide range of industries, from woodworking to tobacco processing and corrugated paper slitting. Their hardness, wear resistance, and precision cutting capabilities make them ideal for applications requiring high performance and reliability. At Huaxin Cemented Carbide, we manufacture tungsten carbide blades custom, altered standard, and standard blanks and preforms, starting from powder through finished ground blanks, catering to the diverse needs of these industries.

For more information about our tungsten carbide blades and their applications, please contact:

- Email: lisa@hx-carbide.com

- Website: https://www.huaxincarbide.com

- Tel & Whatsapp: +86-18109062158

Experience the benefits of tungsten carbide blades in your industry today.

Post time: Mar-18-2025