Essential Cutting Tool in Industrial Applications

Tungsten Carbide Blade

What is Tungsten Carbide?

Tungsten carbide is a compound formed from tungsten and carbon. It has a hardness close to that of diamonds, which enables tungsten carbide blades to cut through hard materials effortlessly.

Tungsten carbide is typically created by blending tungsten carbide powder with cobalt powder, then pressing and sintering it into desired shapes. This results in an incredibly tough material that is not only resistant to wear but also capable of maintaining its edge for extended periods, even when used under high-pressure applications.

Characteristics of Tungsten Carbide Blades

The qualities that set tungsten carbide blades apart from traditional steel blades include:

- Exceptional Hardness: Tungsten carbide’s hardness helps retain a sharp edge longer than other materials.

- Wear Resistance: High resistance to abrasion, which enhances the blade's longevity.

- Thermal Stability: These blades can withstand high temperatures, making them suitable for high-speed cutting.

- Corrosion Resistance: Tungsten carbide resists rust and corrosion, which is essential for blades used in humid or corrosive environments.

- Low Friction: The low friction coefficient contributes to smoother cuts and less heat generation.

Applications of Tungsten Carbide Blades

Thanks to these properties, tungsten carbide blades are extensively used in industries such as:

- Manufacturing: For cutting hard metals, plastics, and composite materials.

- Woodworking: For precision cutting, grinding, and shaping of wood.

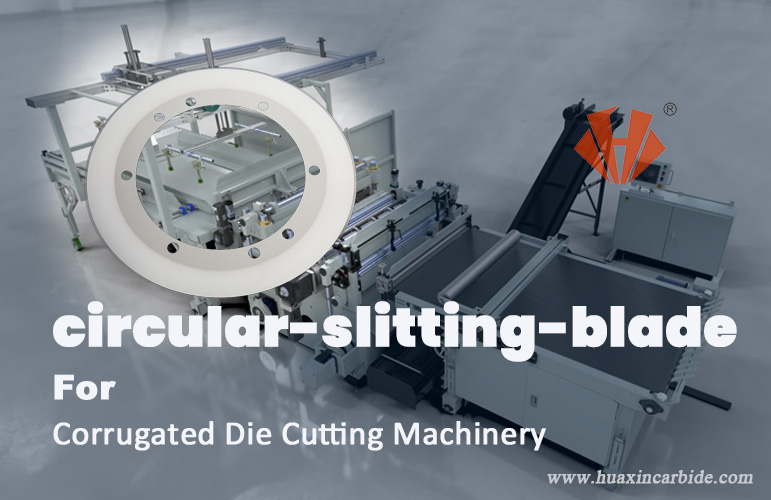

- Packaging: Used in slitting and cutting packaging materials, including films and foils.

- Paper and Printing: Cutting or slitting paper, rubber, and other soft materials with a high degree of precision.

- Textile Industry: Tungsten carbide blades are also used for fabric and textile cutting in large production settings.

4. Tungsten Carbide Blades Market in China

China is a leading producer and consumer of tungsten carbide blades, thanks to its extensive industrial manufacturing base. Chinese manufacturers of tungsten carbide blades cater to both domestic and international markets with a variety of options that meet diverse industrial needs.

The Chinese tungsten carbide blade market is characterized by several factors:

- High Production Volume: Chinese manufacturers produce tungsten carbide blades in large quantities, which often results in competitive pricing.

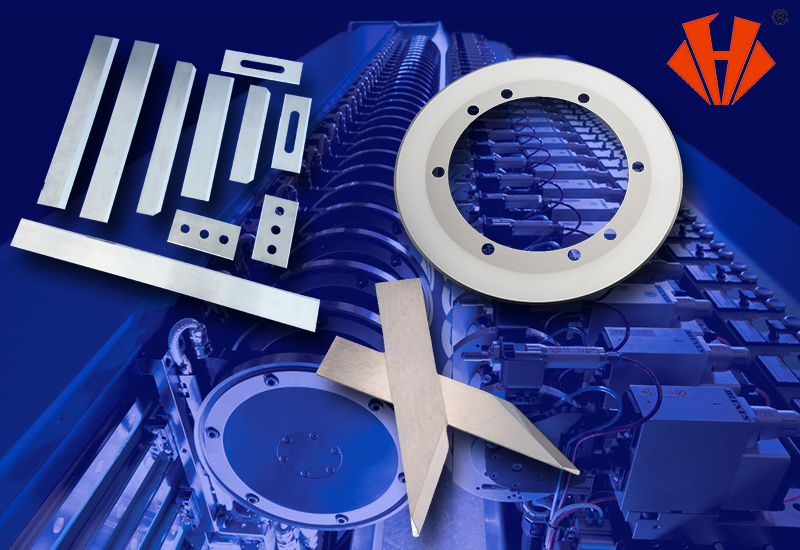

- Wide Range of Products: The market offers a broad spectrum of blade types tailored for specific applications, from slitting knives to industrial machine cutters.

- Quality and Technological Advancements: In recent years, Chinese manufacturers have invested heavily in R&D, resulting in improved blade quality and durability.

- Customization Options: Many manufacturers offer customized blades, catering to industries with specialized requirements.

5. Market Pricing

The pricing of tungsten carbide blades in China varies based on several factors, including blade dimensions, carbide grade, and production volumes. Typical price points for standard tungsten carbide blades in China range between:

- Low-End Blades: Around $10-$20 per blade, generally used for less demanding applications.

- Mid-Range Blades: Priced between $20-$50, these blades are suited for industrial use in moderate-duty applications.

- High-End Blades: Premium quality blades, often costing above $50 per blade, are preferred for heavy-duty applications due to their superior wear resistance and longevity.

6. Chengdu Huaxin Cemented Carbide Company: A Leading Manufacturer

Chengdu Huaxin Cemented Carbide Company is one of the leading players in China’s tungsten carbide blade industry. Known for its high-quality manufacturing standards and commitment to technological innovation, Huaxin has established a strong reputation in both domestic and international markets.

Why Choose Chengdu Huaxin Cemented Carbide?

- Quality Standards: Huaxin’s products adhere to strict quality standards, ensuring reliability and performance.

- Advanced Manufacturing Facilities: The company employs state-of-the-art manufacturing equipment and technology to produce blades that meet precise specifications.

- Wide Range of Products: Huaxin offers various types of tungsten carbide blades for different industries, including custom options tailored to specific needs.

- Competitive Pricing: The company’s large-scale production and efficient processes enable it to offer competitive prices without compromising on quality.

- After-Sales Service: Huaxin is known for its excellent customer service, providing technical support and guidance to ensure optimal product performance.

7. Challenges in the Tungsten Carbide Blade Industry

Although tungsten carbide blades are highly effective, manufacturers face certain challenges in the industry, including:

- Cost of Raw Materials: Tungsten carbide is a costly material, and fluctuations in raw material prices can impact production costs.

- Technological Requirements: The production of tungsten carbide blades demands advanced technology, which not all manufacturers can afford.

- Environmental Impact: Tungsten mining and processing can have environmental consequences, leading some countries to impose stricter regulations on production.

8. Future Outlook

The demand for tungsten carbide blades is expected to grow steadily, especially in sectors like manufacturing, automotive, and woodworking. Innovations in carbide blade coatings and production methods are anticipated to improve their performance further. Additionally, as manufacturers continue to seek cost-effective and durable cutting tools, tungsten carbide blades will remain indispensable.

Post time: Nov-12-2024