In the textile industry, precision, durability, and efficiency are paramount. Among the various tools employed, tungsten carbide blades have emerged as a game-changer due to their superior properties. This article delves into the application of tungsten carbide blades in textiles, their advantages, specific roles, and insights on their replacement rates.

Applications in the Textile Industry

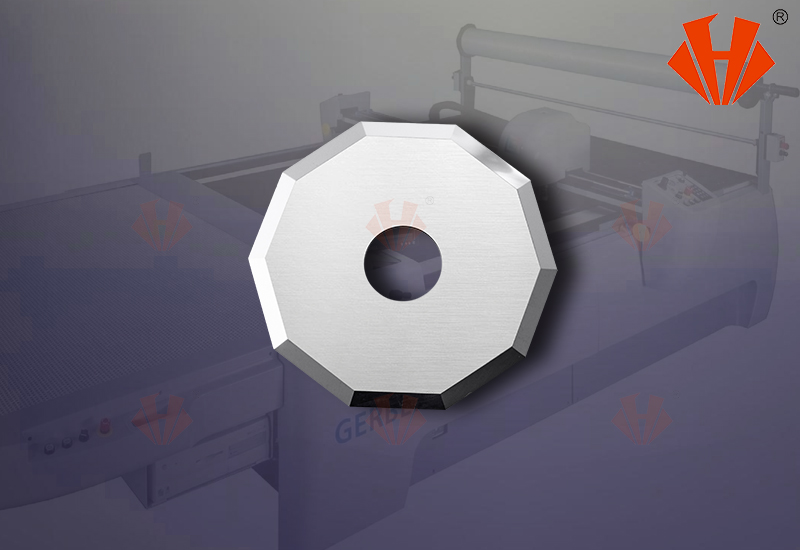

Tungsten carbide blades are extensively used across several applications in the textile sector:

- Cutting Fabrics: For cutting through a wide array of fabrics, from delicate silks to tough denim, tungsten carbide blades are preferred for their sharpness and longevity. They are used in both manual cutting tools and automated cutting machines.

- Slitting Operations: In the production of tapes, ribbons, or any narrow fabrics, these blades are crucial for slitting processes where precision is required to maintain consistent width.

- Shearing Machines: Shearing machines equipped with tungsten carbide blades are used for trimming, shaping, and finishing textiles, ensuring clean cuts without fraying or damaging the material.

- Dyeing and Finishing: Blades are also used in processes like cutting dyed fabrics or finishing edges, where durability under wet conditions is necessary.

Advantages of Tungsten Carbide Blades

Tungsten carbide blades offer several advantages that make them ideal for textile applications:

- Exceptional Hardness: With a hardness rating that rivals diamond, these blades maintain sharpness for extended periods, essential for cutting through thousands of yards of fabric without dulling.

- Durability: They resist wear and tear, reducing the frequency of blade changes and associated downtime, thereby increasing operational efficiency.

- Precision: The blades provide clean, accurate cuts, which is critical in maintaining the quality of high-end textiles.

- Heat and Chemical Resistance: Tungsten carbide can withstand the high temperatures and chemical exposures often encountered in textile processing, which minimizes blade degradation.

- Cost-Effectiveness: Although initially more expensive than steel blades, their longevity offers significant savings over time due to less frequent replacements.

Role of Tungsten Carbide Blades

The primary role of tungsten carbide blades in textiles is to ensure high-quality cuts that enhance product quality and reduce waste. They:

- Enhance Cutting Efficiency: By maintaining sharpness, they allow for faster cutting speeds without sacrificing precision.

- Minimize Material Waste: Precision cutting reduces fabric waste, which is both economically and environmentally beneficial.

- Support Automation: Many modern textile cutting machines are designed to work with these blades, supporting automation for consistent and high-volume production.

Replacement Rate and Maintenance

Along with material advancements, high-hardness tungsten carbide cutting tools also require higher craftsmanship since, no matter how excellent the tungsten carbide materials are, they must be better when the craftsmanship satisfies the requirements. Production needs, for instance, make it difficult to restore the original hardness of high-quality tungsten carbide following degradation because of high temperature and the manufacturer’s inability to create the material. There are several hot environments used in the forming and welding processes used to make these tools. Without advanced technology, the high temperature will cause the tungsten carbide substance to degrade.

- Turnover Rate: The replacement rate of tungsten carbide blades in textiles varies based on usage intensity, but they generally outlast steel counterparts by a significant margin, often by 50 to 500 times in terms of wear life.

- Maintenance and Sharpening: Unlike steel, tungsten carbide blades require specialized sharpening tools due to their high hardness. While they can be resharpened, it’s often more cost-effective to replace them after significant use because resharpening might not restore the initial sharpness to the same degree.

- Signs for Replacement: Blades should be replaced when they show signs of chipping, excessive wear, or when cutting quality diminishes noticeably. Operators need to monitor blade performance closely, especially in high-volume environments.

Tungsten carbide blades have transformed cutting operations in the textile industry, offering unmatched durability and precision. Their role extends beyond mere cutting; they are pivotal in enhancing productivity, reducing costs, and ensuring the high quality of textile products. While the initial investment might be higher, the long-term benefits in terms of reduced replacement frequency and maintenance make them a wise choice for textile manufacturers aiming for efficiency and excellence in production.This overview highlights why tungsten carbide has become an indispensable material in modern textile manufacturing, underlining its role in pushing the boundaries of what’s possible in fabric processing.

Huaxin Cemented Carbide(https://www.huaxincarbide.com) manufactures tungsten carbide blades custom, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industry

Custom-engineered blades

Leading manufacturer of industrial blades

Contact us: lisa@hx-carbide.com

Tel&Whatsapp:86-18109062158

Post time: Jan-20-2025