Introduction

Tobacco processing is a meticulous industry that requires precision and reliability in every step, from leaf cutting to packaging. Among the various tools used in this process, tungsten carbide blades stand out for their exceptional performance. This article explores the role of tungsten carbide blades in tobacco manufacturing, emphasizing their sharpness, reliability, and impact on production efficiency.

The Importance of Tungsten Carbide Blades in Tobacco Manufacturing

Cutting Leaves with Precision

In tobacco manufacturing, the quality of the cut leaves directly impacts the final product. Tungsten carbide blades offer unparalleled precision in cutting tobacco leaves, ensuring a consistent and uniform size. This precision is crucial for maintaining the desired flavor and texture of the tobacco.

According to industry experts, tungsten carbide blades provide cleaner cuts with minimal tear-out, preserving the integrity of the tobacco leaves. Their hardness and wear resistance enable them to maintain a sharp edge for extended periods, ensuring consistent cutting performance throughout the production process.

Slitting Tools for Packaging Materials

In addition to cutting tobacco leaves, tungsten carbide blades are also used as slitting tools for packaging materials. The sharpness and durability of these blades ensure clean and efficient slitting of packaging films and foils, enhancing the overall aesthetics and functionality of the tobacco products.

The reliability of tungsten carbide blades in high-volume production settings is another significant advantage. In tobacco manufacturing, where production volumes can be extremely high, the ability to rely on consistent and reliable cutting performance is crucial for maintaining production efficiency.

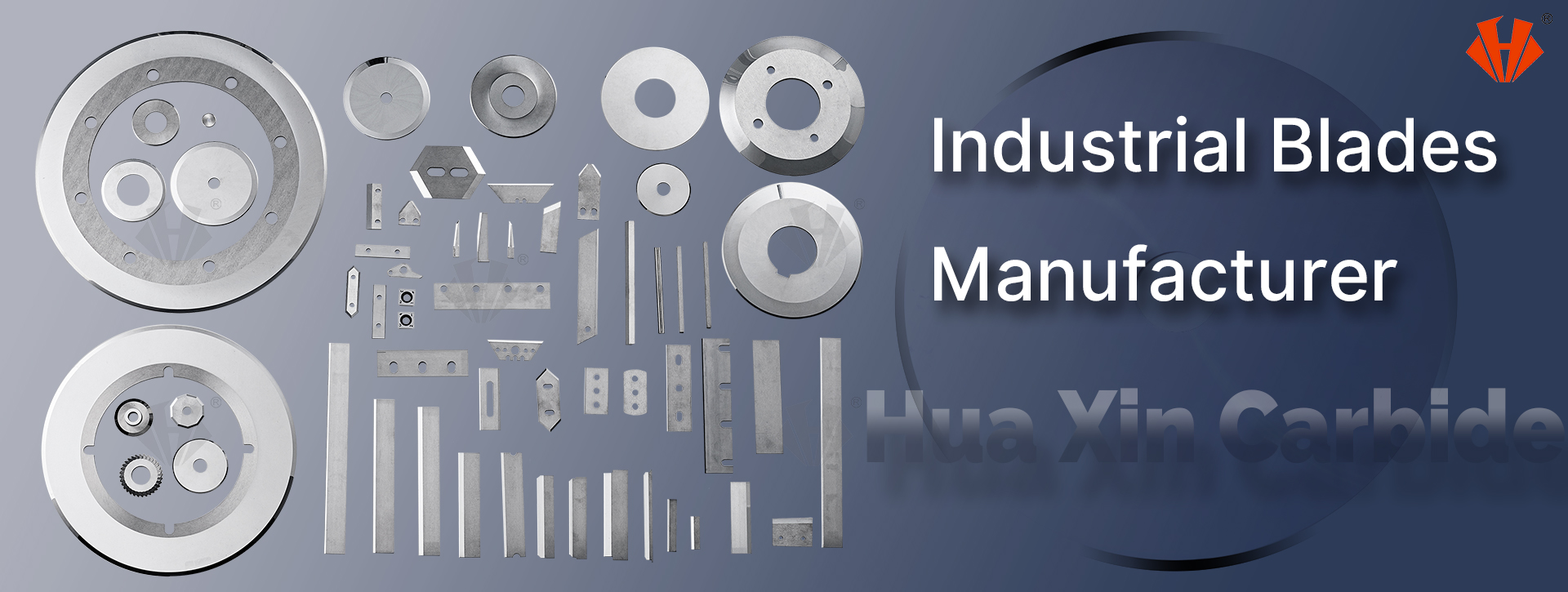

Huaxin: A Specialist in Cemented Carbide Industrial Knives and Blades

Huaxin is a national high-tech enterprise specializing in the research, development, manufacturing, and sales of cemented carbide industrial knives and blades for more than 20 years. With extensive experience in the tobacco processing industry, Huaxin understands the unique challenges and requirements of this sector.

Huaxin’s tungsten carbide blades are designed specifically for tobacco manufacturing, incorporating advanced materials and manufacturing techniques to ensure maximum sharpness, durability, and reliability. Their blades are used in various tobacco processing applications, from leaf cutting to packaging material slitting, contributing to the overall efficiency and quality of the production process.

Contact Information

For more information about Huaxin’s tungsten carbide blades and other industrial knife solutions for tobacco processing, please contact:

- Email: lisa@hx-carbide.com

- Website: https://www.huaxincarbide.com

- Tel & Whatsapp: +86-18109062158

Conclusion

Tungsten carbide blades play a crucial role in tobacco manufacturing, providing precision cutting and reliability in high-volume production settings. Their sharpness, durability, and ability to maintain consistent cutting performance throughout the production process make them indispensable tools in the tobacco processing industry. With Huaxin as a specialist partner, tobacco manufacturers can ensure they have the best tungsten carbide blades for their specific needs, ultimately enhancing production efficiency and product quality.

Post time: Mar-04-2025