Most people only know of carbide or tungsten steel,

For a long time there are many people who do not know that what relationship exists between the two.not to mention people not connected to the metal industry.

What exactly is the difference between tungsten steel and carbide?

Cemented Carbide:

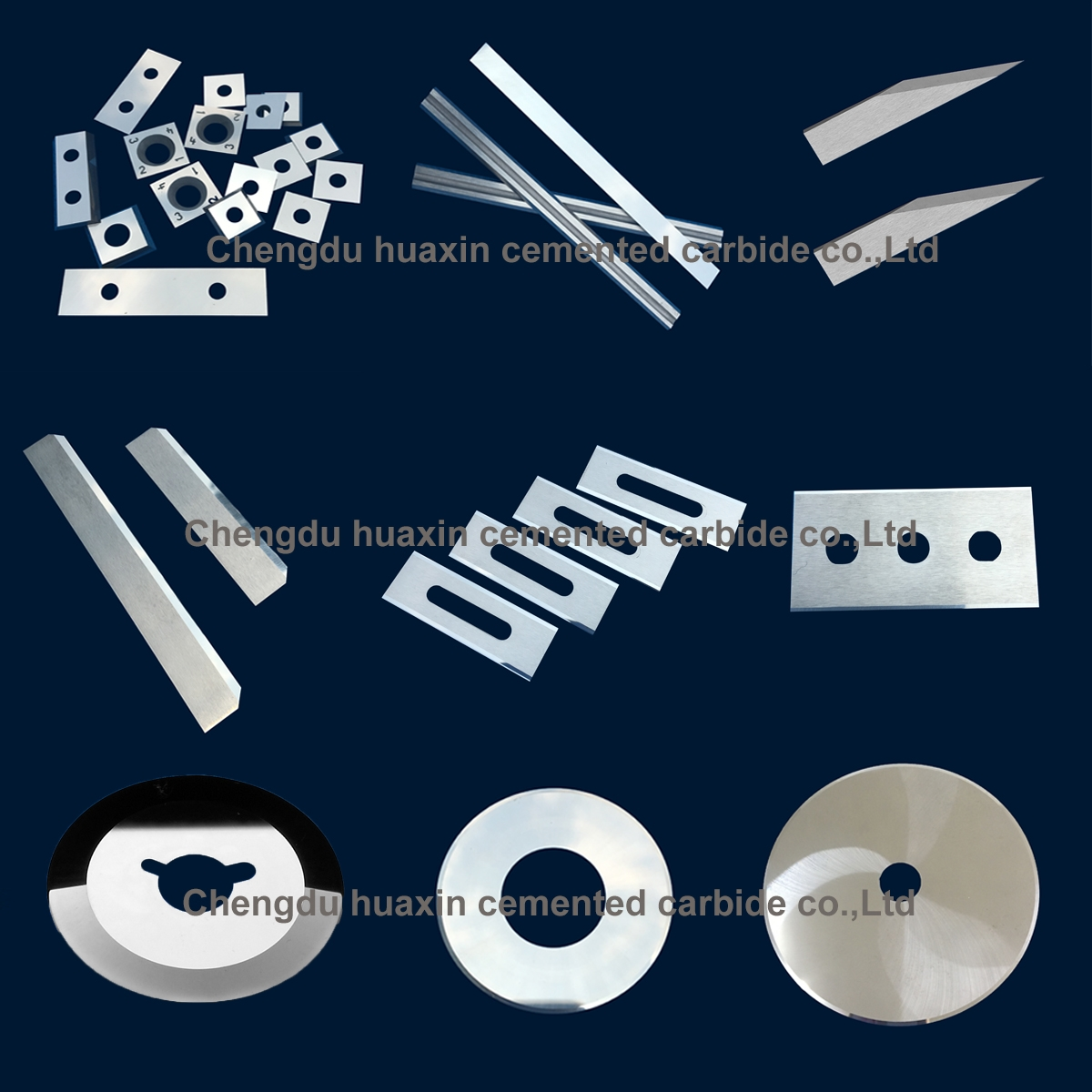

Cemented carbide is made of hard compound of refractory metal and bonded metal through powder metallurgy process, it is a kind of alloy material with high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance, even at a temperature of 500 ℃ also remains basically unchanged, at 1000 ℃ still has a high hardness. This is the reason why the price of cemented carbide is higher than other common alloys.Cemented Carbide Applications:

Cemented carbide is widely used as tool materials, such as turning tools, milling tools, planing tools, drills, boring tools, etc. It is used to cut cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone and ordinary steel, and can also be used to cut heat-resistant steel, stainless steel, high manganese steel, tool steel and other difficult-to-machine materials.

Tungsten Steel:

Tungsten steel is also called tungsten-titanium alloy or high-speed steel or tool steel. The hardness of Vickers 10K, second only to diamond, is a sintered composite material containing at least one metal carbide composition, tungsten steel, cemented carbide have high hardness, wear resistance, strength and toughness, heat resistance, corrosion resistance and a series of excellent properties. The advantages of tungsten steel mainly lie in its high hardness and wear resistance. Easy to be called as the second diamond.

Difference between Tungsten Steel vs Tungsten Carbide:

Tungsten steel is made by adding ferro tungsten as tungsten raw material in steel making process, also called high speed steel or tool steel, its tungsten content is generally 15-25%, while cemented carbide is made by powder metallurgy process with tungsten carbide as the main body and cobalt or other bonding metal together with sintering, its tungsten content is generally above 80%. Simply put, all products with hardness over HRC65 can be called cemented carbide as long as they are alloys.

Simply put tungsten steel belongs to cemented carbide, but cemented carbide is not necessarily tungsten steel.

Post time: Feb-21-2023