Introduction

Tungsten carbide woodworking replacement blades have become a cornerstone in modern woodworking due to their exceptional durability and performance. These blades are designed to enhance precision, efficiency, and longevity in various woodworking applications.

What are Tungsten Carbide Woodworking Replacement Blades?

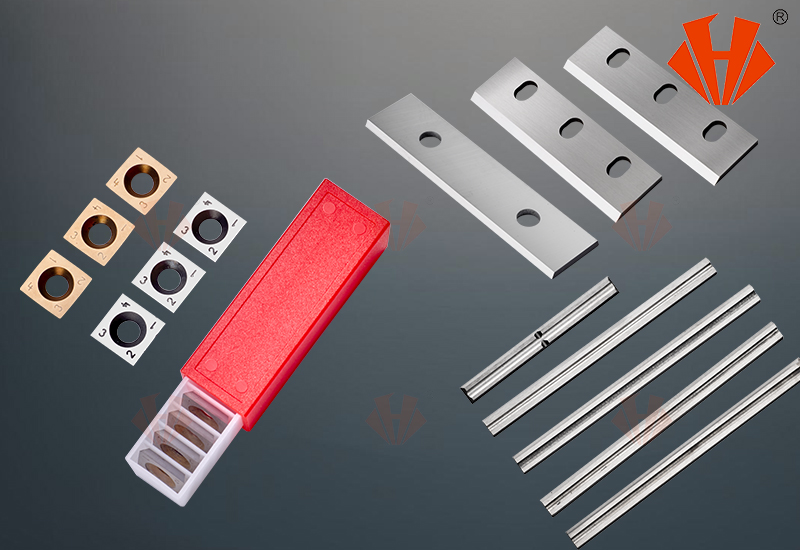

Tungsten carbide replacement blades for woodworking are cutting tools made from a composite of tungsten carbide particles bonded with a metal like cobalt. These blades are specifically engineered for use in woodworking tools such as planers, jointers, and routers. Their design often allows for all four edges to be used, meaning when one edge dulls, the blade can be rotated for a fresh cutting edge, significantly extending its life.

Advantages of Tungsten Carbide Blades

Durability: Tungsten carbide is extremely hard, offering three times the hardness of steel, which translates into blades that last much longer than traditional steel blades.

Edge Retention: These blades maintain their sharpness over an extended period, reducing the need for frequent sharpening and replacements.

Cost Efficiency: Although more expensive upfront, the longevity and the ability to use all four edges significantly reduce long-term costs.

Precision Cutting: The blades provide cleaner, more accurate cuts, which is essential for high-quality woodworking projects.

Resistance: They are resistant to heat, which helps in maintaining cutting performance during long sessions of use.

Applications in Woodworking

Portable Electric Planers: For smoothing and sizing wood, tungsten carbide blades offer unmatched service life over conventional HSS blades.

Stationary Woodworking Machines: Used in jointers, thickness planers, and moulders where consistent, high-quality cuts are required.

Hand Tools: Certain specialized hand tools like chisels and gouges can benefit from tungsten carbide tips for longevity.

Wood Shaping and Finishing: Ideal for applications where detailed work or finishing touches are needed without rapid blade wear.

Market Analysis

Market Size and Growth: The global tungsten carbide market, including woodworking applications, is growing at a CAGR of around 3.5% to 7.5% over the next few years, driven by demand in manufacturing, construction, and woodworking sectors.

Key Players: Companies like Zigong Xinhua Industrial Co. Ltd. and Baucor specialize in producing high-quality tungsten carbide tools for woodworking.

Market Trends: There’s a trend towards automation and precision in woodworking, increasing the demand for durable, high-performance blades like those made from tungsten carbide.

Top Importing Countries

China: As one of the largest manufacturers and consumers of woodworking tools, China imports significant quantities of tungsten carbide products to meet domestic demand and for re-export.

United States: With a robust woodworking and construction industry, the U.S. imports tungsten carbide blades for both professional and DIY markets.

Germany: Known for precision engineering, Germany imports high-quality tungsten carbide tools for its manufacturing sectors.

Japan: Japan’s industry, particularly in precision woodworking, also relies on imports of these blades.

Market Challenges

Raw Material Costs: Fluctuations in tungsten prices can impact the cost-effectiveness of these blades.

Environmental Regulations: Tungsten mining and processing can be environmentally hazardous, leading to stringent regulations that affect production costs.

Competition from Alternatives: New materials and technologies might challenge tungsten carbide’s market dominance in specific applications.

Tungsten carbide woodworking replacement blades represent a significant advancement in woodworking technology, offering benefits in durability, precision, and cost over time. The market for these blades is notably influenced by industrial demands in countries like China, the United States, Germany, and Japan. As woodworking continues to evolve with automation and high-quality standards, the demand for superior cutting tools like tungsten carbide blades is expected to grow, driven by both the need for efficiency and the push towards sustainable practices in manufacturing.

HUAXIN CEMENTED CARBIDE provides premium tungsten carbide knives and blades for our customers from different industries across the world.The blades can be configured to fit machines used in virtually any industrial application. Blade materials, edge length and profiles, treatments and coatings can be adapted for use with many industrial materials

Contact us: lisa@hx-carbide.com

https://www.huaxincarbide.com

Tel&Whatsapp:86-18109062158

Post time: Apr-08-2025