Understanding Turnover Knives and Their Benefits in Various Industries

What Are Turnover Knives?

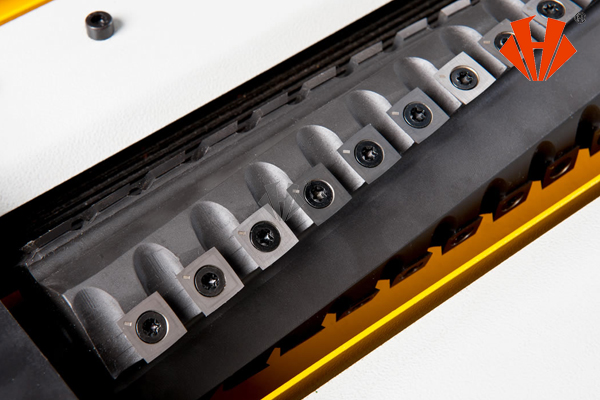

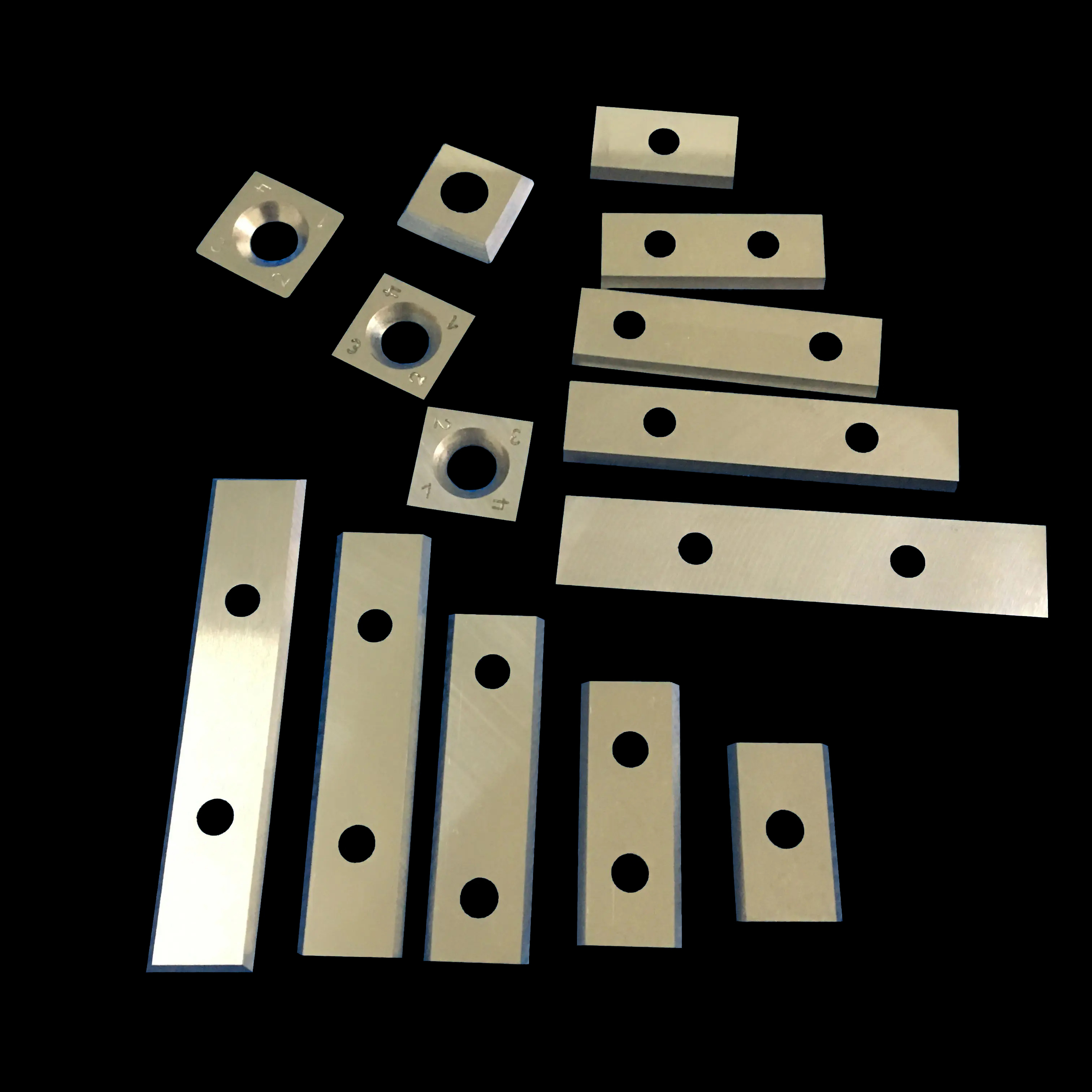

Turnover knives are cutting tools that feature two edges, allowing them to be flipped over for extended use. This dual-edge functionality is a key feature that enhances the lifespan and efficiency of the tool, reducing downtime and the cost of replacements. These knives are widely used in equipment like grooving cutterheads, table shapers, and edgebanding machinery, where precision cutting and longevity are paramount.

Carbide Reversible Blades and Their Advantages

Carbide reversible blades are a popular choice for turnover knives due to their exceptional performance and cost-effectiveness. The main advantage of reversible blades is that they can be flipped once one side wears out, doubling the usable life of the knife. Made from high-performance carbide, these blades are highly resistant to wear and can withstand high-speed cutting applications. This makes them ideal for industries such as woodworking, where frequent tool replacements could lead to significant downtime.

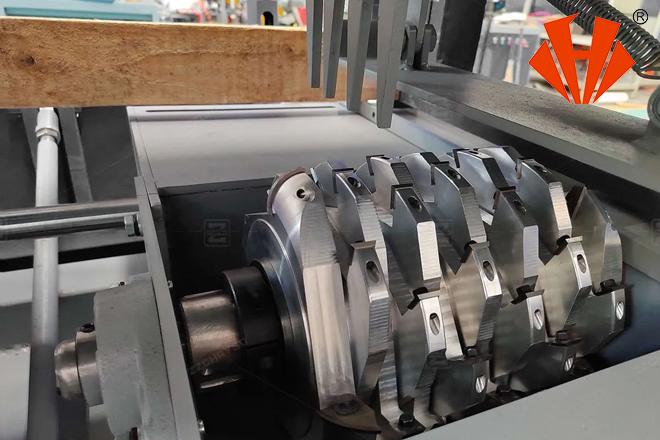

Carbide Indexable Inserts and Their Role in Turnover Knives

Carbide indexable inserts are another common feature in turnover knives, particularly in woodworking and metalworking. These inserts are designed to be replaced individually when they become dull, instead of replacing the entire blade. The key advantage of carbide inserts is their ability to maintain a sharp cutting edge for longer periods, even under heavy use. The interchangeability of the inserts allows for quick and easy blade changes, making maintenance more efficient and reducing operational costs.

The use of carbide indexable inserts also ensures a higher level of cutting precision, as the inserts are precision-engineered to fit perfectly into the knife holder. In addition, they are available in various geometries, allowing for customization depending on the specific cutting needs of the application.

Solid Carbide Turnover Knives

For applications requiring the highest level of durability and cutting precision, solid carbide turnover knives are often the preferred choice. These knives are made entirely from carbide material, offering superior hardness and wear resistance compared to conventional steel knives. Solid carbide turnover knives excel in high-precision tasks such as grooving, shaping, and trimming, where a sharp and consistent edge is critical.

These knives are particularly effective in industries like furniture manufacturing, where intricate and delicate cuts are required on materials like wood and laminated boards. Solid carbide knives can endure the stresses of these operations without dulling quickly, ensuring that production remains efficient.

These knives are often made from durable materials like carbide or high-speed steel (HSS), with carbide being particularly favored for its hardness and resistance to wear. In woodworking, turn over knives are used in planers, jointers, and milling machines, where they help maintain precision and clean cuts across various types of wood. Additionally, carbide reversible knives are highly valued for their ability to handle hardwoods without dulling as quickly as traditional steel knives.

Long wearing carbide insert knives 14.6x14.6x2.5mm are offered for planer and jointer machines with spiral helical cutterhead, planer sander machine, groover, moulder cutterhead and other woodworking applications.

Overall, turn over knives are a practical, cost-effective solution in industries requiring high precision and long-lasting cutting tools.

Grooving Turnover Knives and Grooving Carbide Insert Knives

One of the most common applications for turnover knives is in grooving cutterheads. Grooving turnover knives are specifically designed to cut grooves into materials, making them ideal for applications such as joinery, panel making, and decorative wood cutting. These knives are available in various designs, including carbide insert knives that combine the benefits of carbide’s durability with the flexibility of replaceable inserts.

Grooving carbide insert knives offer versatility and long-lasting performance, as they can be easily swapped out for new inserts when they become worn, without the need to replace the entire knife. This feature makes them a cost-effective solution for industries with high-volume production needs.

Tungsten Carbide Tipped (TCT) Turnover Knives

In certain high-demand cutting environments, Tungsten Carbide Tipped (TCT) turnover knives are used. TCT knives combine the toughness of a steel blade with the wear resistance and hardness of tungsten carbide, making them suitable for cutting through tough materials like hardwoods and composites. TCT turnover knives offer high cutting performance, particularly in applications such as wood molding, edge finishing, and veneer processing.

The use of Tungsten Carbide Turnover Knives in these applications ensures a longer tool life, which is especially important in industries where productivity and efficiency are critical. By providing longer service intervals between tool changes, TCT turnover knives contribute to lower operating costs over time.

Dual-Edge and Multi-Edge Carbide Turnover Knives

Dual-edge carbide knives and multi-edge carbide inserts are another innovative design for turnover knives. These knives feature multiple cutting edges, such as 4-edge turnover knives or radius turnover knives, allowing for even greater tool life and efficiency. When one edge becomes dull, operators can simply rotate the knife to use the next sharp edge. This design significantly reduces downtime and increases overall productivity.

For applications that require complex cutting geometries, radius turnover knives provide precision in tasks that involve curved or angled cuts. These knives can maintain a consistent cut quality and help to ensure the smoothness and accuracy of the finished product.

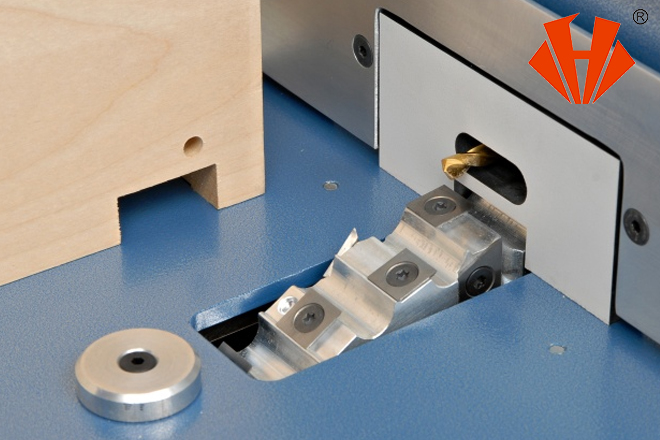

Knives for Table Shapers and Edgebanding

In addition to their use in grooving and shaping, turnover knives are also crucial in machines like table shapers and edgebanding equipment. Insert carbide tips for woodworking are particularly useful in these settings, where the knives must provide consistent, smooth cuts on wooden pieces and edges. Edgebanding insert knives, which are used in machines that apply protective edging to furniture or cabinetry, are designed to deliver a flawless finish while ensuring that the cutting edges remain sharp throughout long runs.

Dual-Edge and Multi-Edge Carbide Turnover Knives

Dual-edge carbide knives and multi-edge carbide inserts are another innovative design for turnover knives. These knives feature multiple cutting edges, such as 4-edge turnover knives or radius turnover knives, allowing for even greater tool life and efficiency. When one edge becomes dull, operators can simply rotate the knife to use the next sharp edge. This design significantly reduces downtime and increases overall productivity.

For applications that require complex cutting geometries, radius turnover knives provide precision in tasks that involve curved or angled cuts. These knives can maintain a consistent cut quality and help to ensure the smoothness and accuracy of the finished product.

Knives for Table Shapers and Edgebanding

In addition to their use in grooving and shaping, turnover knives are also crucial in machines like table shapers and edgebanding equipment. Insert carbide tips for woodworking are particularly useful in these settings, where the knives must provide consistent, smooth cuts on wooden pieces and edges. Edgebanding insert knives, which are used in machines that apply protective edging to furniture or cabinetry, are designed to deliver a flawless finish while ensuring that the cutting edges remain sharp throughout long runs.

Huaxin Carbide: Leading the Industry in Turnover Knife Manufacturing

One prominent manufacturer of high-quality turnover knives is Huaxin Carbide, a Chinese company that specializes in the production of carbide tools for woodworking and metalworking applications. Known for their precision and high-performance products, Huaxin Carbide produces a wide range of turnover knives, including solid carbide turnover knives, Tungsten carbide tipped turnover knives, and grooving carbide insert knives. With a focus on durability and cutting precision, Huaxin Carbide has become a trusted supplier to industries that require high-quality cutting tools for their operations.

Turnover knives, particularly those made with carbide and tungsten carbide materials, offer superior performance and extended tool life. Whether used in woodworking, metalworking, or other manufacturing applications, these knives provide cost-effective and efficient solutions for precision cutting. The versatility of reversible blades, indexable inserts, and dual-edge knives makes them invaluable in high-volume environments. Manufacturers like Huaxin Carbide are at the forefront of providing these advanced tools, ensuring that industries around the world can meet their production demands while maintaining quality and efficiency.

Post time: Nov-13-2024