What are the materials of tungsten carbide blades in woodworking? what tungsten carbide blades should be your first choice?

Materials of Tungsten Carbide Blades: Tungsten carbide blades are primarily made from tungsten carbide, which is a compound consisting of tungsten and carbon. This material is known for its exceptional hardness, often rated at a hardness of 9.0 on the Mohs scale, similar to diamond. The manufacturing process involves mixing tungsten powder with carbon powder, then sintering this mixture at high temperatures to form the carbide. In some applications, tungsten carbide is further enhanced with cobalt as a binder, which helps in achieving a balance between hardness and toughness. The cobalt content can vary, affecting the blade’s impact resistance and wear resistance.

Tungsten carbide blades are primarily made from tungsten carbide (WC), which is a compound of tungsten and carbon. This material is known for its hardness, wear resistance, and durability, making it ideal for use in cutting tools, including woodworking blades.

Key Materials in Tungsten Carbide Blades:

Tungsten Carbide (WC): The main component, providing exceptional hardness and wear resistance.

Cobalt (Co): Often used as a binder to hold the carbide particles together, improving toughness and impact resistance.

Nickel (Ni): Sometimes used to improve corrosion resistance.

Titanium or other alloying elements: In some cases, other elements may be added to improve specific characteristics, like thermal stability.

Tungsten Carbide Blades for Woodworking:

When choosing tungsten carbide blades for woodworking, the following factors should guide your decision:

Blade Type:

Planer Blades: For flattening or smoothing wood surfaces, high-quality tungsten carbide planer blades offer long-lasting sharpness and performance.

Spiral Cutter Heads: These provide a smoother finish and are less prone to chipping, which is important for high-quality woodworking.

Saw Blades: Tungsten carbide saw blades are ideal for cutting wood, plywood, and other materials, as they maintain a sharp edge and resist wear.

Router Bits: For fine woodworking, carbide-tipped router bits are popular due to their superior edge retention and smooth cutting performance.

Woodworking Applications:

Softwoods: If you are primarily working with softwoods, blades with a finer grit carbide may be sufficient.

Hardwoods: For dense, hardwood materials, you should choose blades with a tougher carbide formulation, providing greater durability under higher cutting stresses.

First Choice for Tungsten Carbide Blades in Woodworking:

For Planing and Surface Smoothing: Tungsten carbide planer blades and spiral cutter heads should be your first choice, as they provide long-lasting sharpness and smoother finishes.

For Cutting: Tungsten carbide saw blades are excellent for cutting large quantities of wood with minimal wear and tear, especially when dealing with hardwoods or composite materials.

By choosing high-quality tungsten carbide blades that are designed for your specific woodworking tasks, you’ll ensure both efficiency and a longer lifespan for your tools.

For instance, blades with higher cobalt content (around 12-15%) are used for applications involving moderate to high shock loads, while those with lower cobalt (6-9%) are chosen for applications where longer life and wear resistance are prioritized.

Tungsten Carbide Tipped (TCT) Blades: For woodworking, TCT blades are often recommended as a first choice due to their versatility and longevity. These blades have tungsten carbide teeth fused onto a steel body, combining the durability and sharpness retention of carbide with the flexibility of steel. They are suitable for cutting a range of materials from hardwoods to metals and plastics, offering precision and clean cuts. TCT blades are particularly advantageous for their ability to maintain edge sharpness longer than high-speed steel (HSS) blades, which means less frequent sharpening, although they can be more expensive upfront.

Solid Tungsten Carbide Blades: While less common due to brittleness and cost, solid tungsten carbide blades can be an excellent choice for specific applications, such as cutting very abrasive or hard materials where edge retention is critical. However, they are not recommended as a general first choice in woodworking due to their brittleness and difficulty in sharpening.

Blade Selection by Application: When selecting your first tungsten carbide blade, consider the type of wood you’ll be working with. For softwoods or general woodworking, a TCT blade with a medium cobalt content might suffice. For hardwoods, you might want to look into blades with specific edge geometries designed for toughness, like those with a 40º included edge angle for applications involving shock loads.

For most woodworkers starting with tungsten carbide, a TCT blade would be the practical first choice, providing a balance between cost, performance, and ease of use across various woodworking tasks.

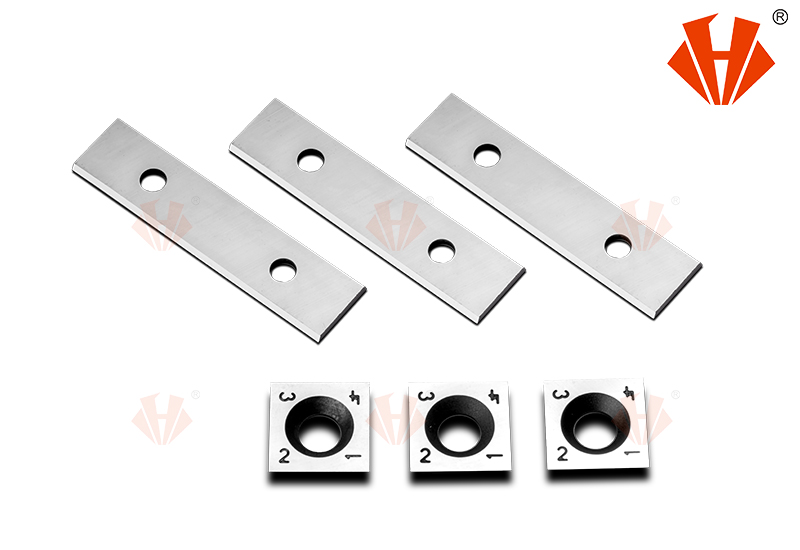

Reversible Planer Blades Knives are made of a premium carbide grade and are individually inspected to ensure quality and accuracy. Planer blades are used when working on wooden surfaces to help create perfectly planned surfaces. They can also be used to chamfer, and rebate edges. The size of the blade refers to the size of the planer that it will fit. It will outlast conventional HSS blades at least 20 times and produce a smoother, cleaner finish.

Huxin Cemented Carbide(www.huaxincarbide.com) focuses on using advanced materials and manufacturing processes to produce blades that excel in hardness, wear resistance, and sharpness. Their expertise in carbide technology makes them a trusted partner for businesses in need of high-quality woodworking carbide blades.

Contact: lisa@hx-carbide.com

Post time: Jan-08-2025