Introduction

Woodworking is an intricate craft that demands precision, durability, and efficiency from the tools used. Among the various cutting tools available, tungsten carbide blades stand out for their exceptional performance in wood processing. This article explores why tungsten carbide blades are the preferred choice for woodworkers, focusing on their cutting precision, blade durability, and tips for maximizing their use in this industry.

Cutting Precision

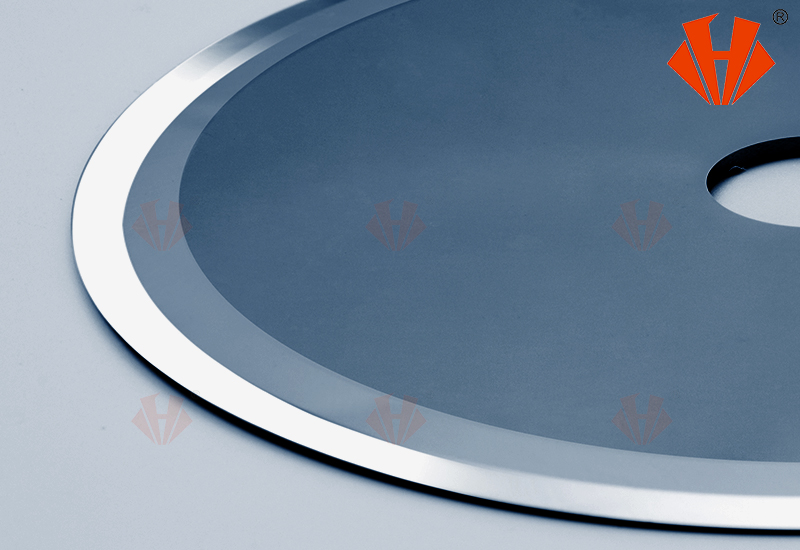

Tungsten carbide blades excel in woodworking due to their unparalleled cutting precision. The hardness and wear resistance of tungsten carbide enable these blades to maintain a sharp edge for extended periods, ensuring clean and accurate cuts. This precision is crucial in woodworking, where even minor imperfections can compromise the final product’s quality.

According to industry experts, tungsten carbide blades provide a cleaner cut with less tear-out compared to traditional steel blades. This is particularly beneficial when working with delicate woods or intricate designs where precision is paramount.

Blade Durability

Another significant advantage of tungsten carbide blades in woodworking is their durability. The material’s resistance to wear and tear means these blades can withstand extensive use without significant degradation. This durability translates to longer tool life and reduced maintenance requirements, ultimately saving time and costs for woodworkers.

In wood processing environments where blades are subjected to continuous use and abuse, tungsten carbide blades offer a reliable and long-lasting solution. Their ability to retain sharpness over extended periods reduces the frequency of sharpening and blade replacement, enhancing overall productivity.

Applications in Woodworking

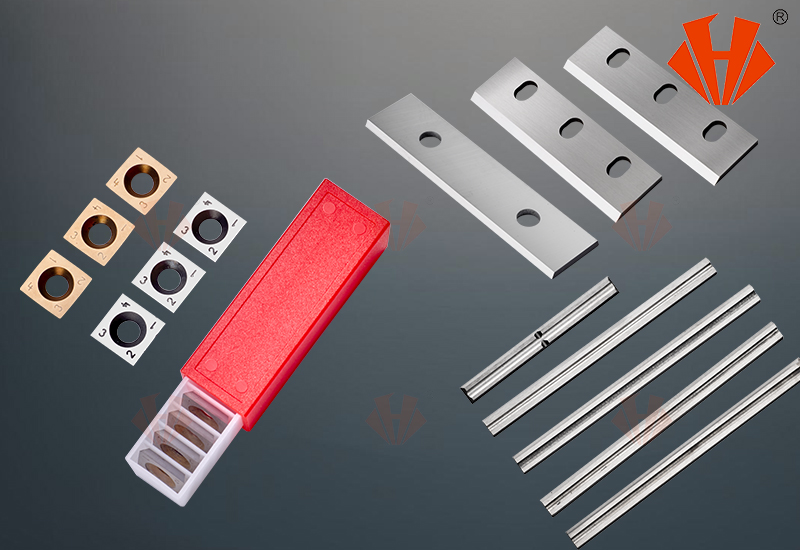

Tungsten carbide blades find applications in various woodworking processes, including sawing and planing. In sawing, they provide clean and efficient cuts through various wood types, from softwoods to hardwoods. In planing, their precision and durability ensure smooth and even surfaces, enhancing the finished product’s aesthetics and functionality.

Woodworkers can further optimize the performance of tungsten carbide blades by following best practices such as maintaining the correct blade angle, using appropriate feed rates, and ensuring adequate lubrication to minimize friction and heat build-up.

Huaxin: Your Reliable Partner in Industrial Machine Knives and Blades

When it comes to sourcing high-quality tungsten carbide blades for woodworking, Huaxin stands out as a reliable partner. As an Industrial Machine Knife Solution Provider, Huaxin offers a comprehensive range of industrial slitting knives, machine cut-off blades, crushing blades, cutting inserts, carbide wear-resistant parts, and related accessories.

Huaxin’s products are used in more than 10 industries, including corrugated board, lithium-ion batteries, packaging, printing, rubber and plastics, coil processing, non-woven fabrics, food processing, and medical sectors. Their expertise in manufacturing tungsten carbide blades ensures that woodworkers can rely on these tools for exceptional performance and durability.

Contact Information

For more information about Huaxin’s tungsten carbide blades and other industrial knife solutions, please contact:

- Email: lisa@hx-carbide.com

- Website: https://www.huaxincarbide.com

- Tel & Whatsapp: +86-18109062158

Tungsten carbide blades are the preferred choice for woodworkers due to their cutting precision, durability, and versatility in various woodworking processes. By partnering with reliable manufacturers like Huaxin, woodworkers can ensure they have the best tools for the job, ultimately enhancing productivity and creating high-quality woodworking products.

Post time: Mar-02-2025