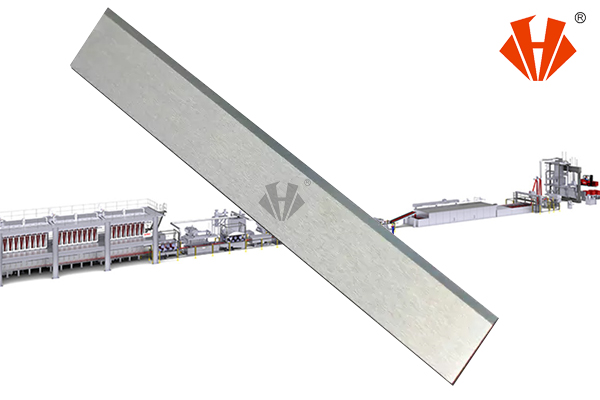

Tungsten Carbide chemical fiber cutter blades /Staple fiber cutter blades

Name:Polyester(PET)Staple Fiber Cutting Blade/Chemical fiber cutter blades

Description:Polyester(PET)Staple Fiber Cutting Blade -MARK V ;MARK IV

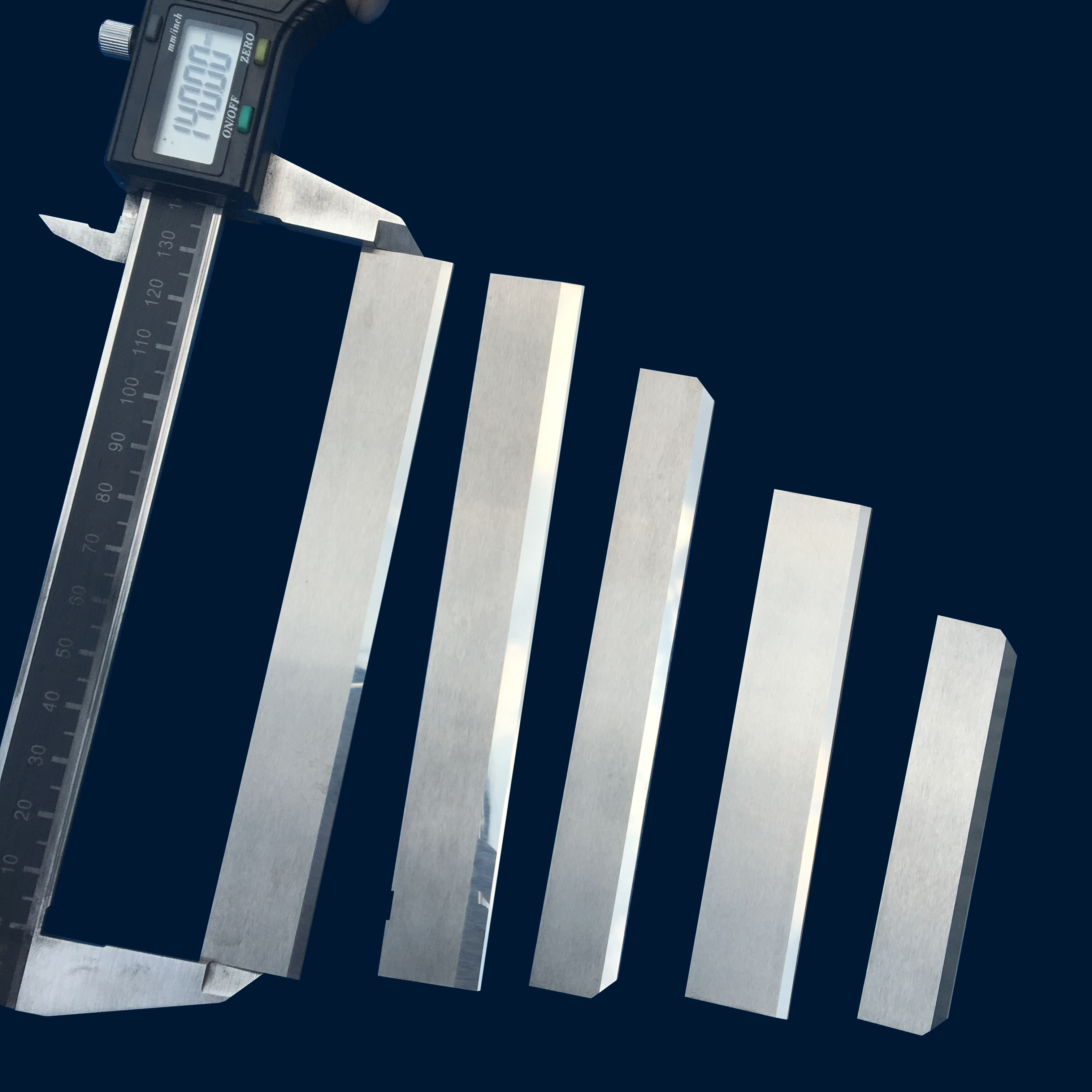

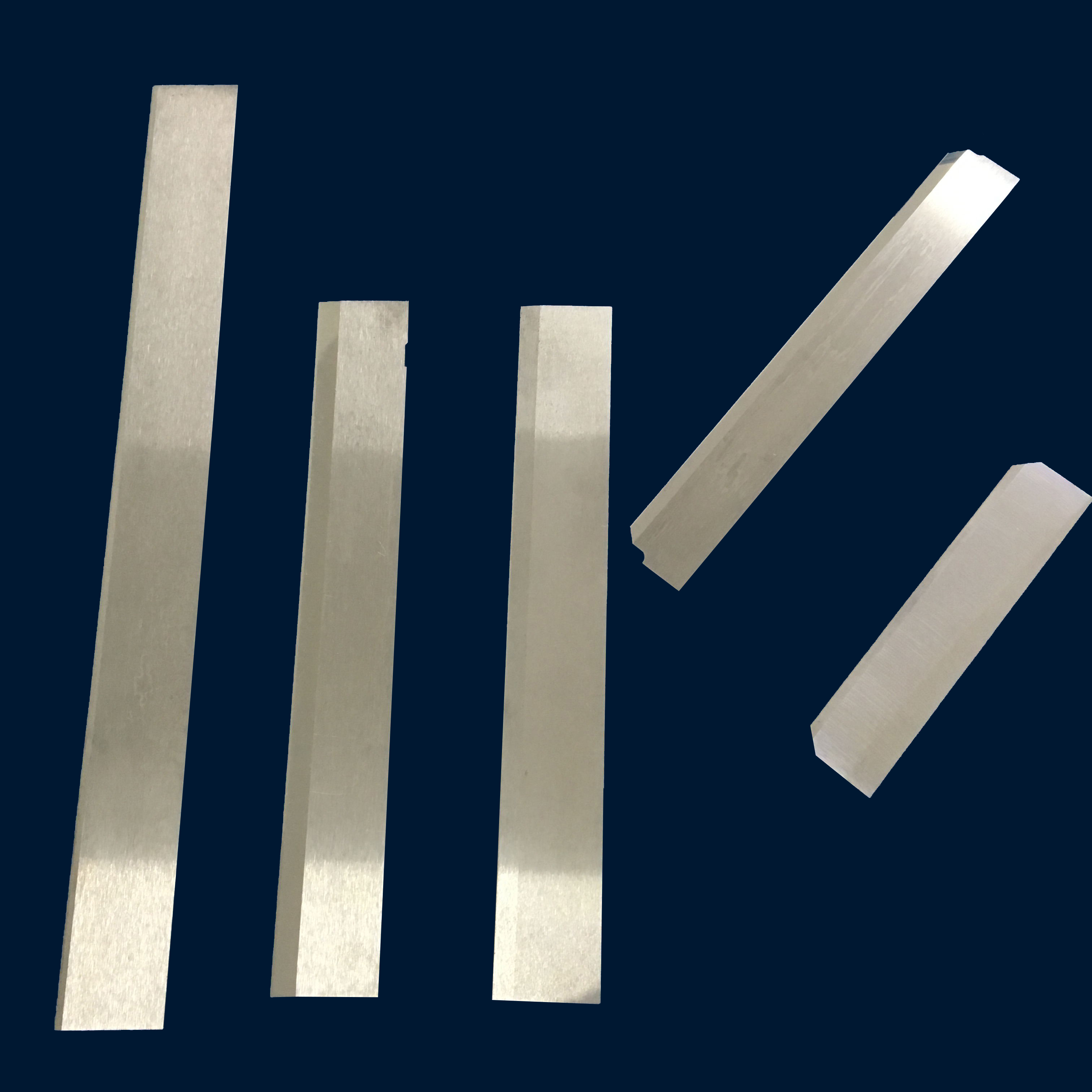

Measurements:117.5x15.7x0.884mm-R1.6 74.6x15.7x0.884mm-R1.6/ Lummus Mark IV Cutting Blades

Note:We provide both industry standard chemical fiber blades(Polyester PET Staple Fiber Cutting Blade) and specialty fiber blades to meet specific needs.

Materials:TUNGSTEN CARBIDE

Carbide grade:Fine /Ultra-fine

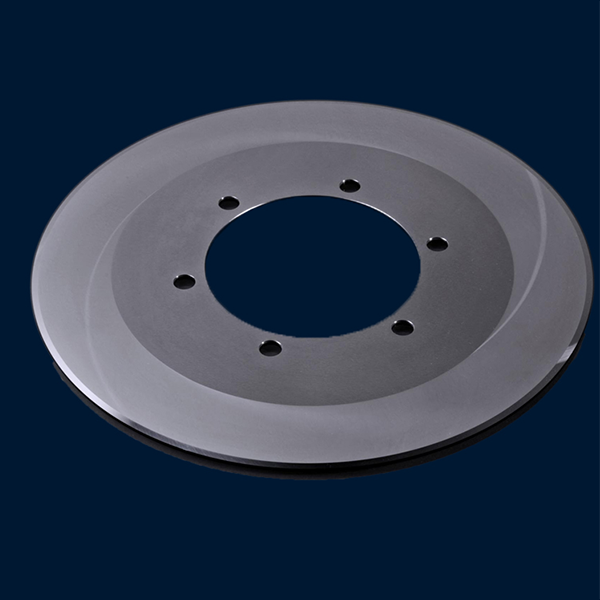

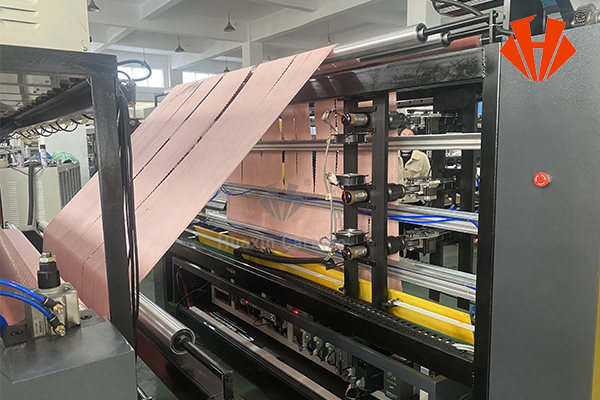

Application:for cutting chemical staple Polypropylene fiber and fiberglass/mask non-woven fabric/synthetic fibers Suit for Most Textiles machines: Staple fibre blades for Lumus, Barmag, Fleissner, Neumag, Zimmer, DM&E

Chemical Fiber Blades are specifically designed to cut synthetic fibers efficiently. These blades are engineered to handle the unique properties of chemical fibers, ensuring clean, precise cuts that enhance the overall quality of the finished product. Fiber Cutting Blades from Huaxin are crafted using advanced tungsten carbide technology, which ensures durability and longevity, reducing the frequency of replacements and maintenance.

For specific applications, such as the cutting of staple fibers, manufacturers often turn to specialized tools like the Fiber Cement Cutting Knife and Staple Fiber Cutting Knife. These tools are essential in producing high-quality staple fibers used in textiles and composite materials. Huaxin's offerings include Chemical Fiber Cutting Blades that excel in cutting through various chemical fiber compositions, providing unmatched efficiency and reliability.

One of the most demanding applications in the fiber cutting industry involves Cutting Blades for Carbon Fiber Fabrics. Carbon fiber is known for its strength and lightweight properties, making it ideal for aerospace and automotive applications. Huaxin’s Industrial Fiber Cutting Blades are specifically designed to tackle the challenges of cutting carbon fiber, ensuring smooth and accurate results.

Why Tungsten Carbide blades for polyester PET/synthetic fiber staple fiber cutting:

Cutting chemical fibres makes very heavy demands on blades. The productivity of state-of-the-art large-scale machines such as those made by Lumus, Barmag, Fleissner, Neumag or Zimmer, depends on a number of factors. One of these is the quality of the staple fibre blades used - and that means blade after blade after blade. In this high-performance application, all materials are applied tungsten carbide are selected after close consultation with the customer. It is only by applying these high-quality staple fibre blades that it is possible to cut every fibre to exactly the same length and prevent frayed fibre ends. Staple fibre blades from HUAXIN CARBIDE meet this requirement - and many more.

Advantages:

Polyester(PET)Staple Fiber Cutting Blade Cutting the polyester/ Poly propylene staple fibers requires blades that are with of very high quality and efficiency.

HUAXIN CARBIDE FIBER CUTTER BLADES:

Long-term, consistent sharpness, Longer machine running up and save downtime of blade changes

High quality tungsten carbide materials,Strictly use pure tungsten carbide ,meet optimum hardness requirements

Blade geometries depend on the type of fibres to be cut,Controlled length of fiber and no unraveling

Adhere to strictly tolerance standards;

Suitable for all standard cutting machines in use in the industry, Higher productivity

Customized service to match your specific process requirements